Apple may be looking to expand the use of sapphire in its iOS lineup, as a new company filing points to larger applications than covers for fingerprint sensors and camera covers, like entire device displays.

When Apple unveiled its iPhone 5s on Tuesday, it debuted a new Touch ID fingerprint sensor that features a unique cover glass made out of sapphire, an incredibly hard stone with a hardness rating second only to diamond. Aside from the sapphire covering used to protect the iPhone 5's rear camera lens element, Apple has not used the material as a major component in its products. That may soon change.

A new patent filing published on Thursday by the U.S. Patent and Trademark Office, simply titled "Sapphire Laminates," shows the company is actively working on processes that can make the expensive gemstone a viable option for the mass production of consumer electronics.

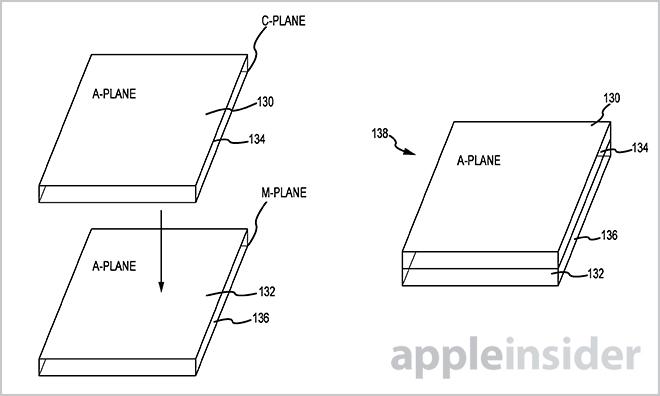

Combining two sheets of sapphire. | Source: USPTO

First filed for in March, the invention looks to alleviate costs associated with preparing sapphire, or corundum, for use as an extremely scratch-resistant display covering or even as part of a device's screen.

As noted in the patent language, the cost of sapphire is only part of the problem. The same properties that make corundum an asset also make it difficult to prepare. Apple gives the example of cutting and polishing the material, which is more time consuming when applying traditional techniques. In addition, the machines are rapidly worn down due to the stone's hardness.

The process outlined in Apple's filing concerns the lamination of sapphire sheets, including sapphire-on-sapphire or sapphire-on-glass applications.

Because sapphire is crystalline in structure, Apple can take advantage of more than one property when laying up two or more sheets and fusing them together. For example, one plane of corundum exhibits high scratch resistance and can be used as an outer layer for a display glass, while a different plane may be less prone to breakage.

Various embodiments of Apple's patent.

Apple says that the final laminated sheet will be no more than 1 millimeter thick, meaning the separate 0.5mm sapphire sheets need to be handled with great care. To create a single solid structure, the sheets are fused together at high temperatures. Adhesives can also be used in some cases. Thicknesses of less than 1mm can be achieved by lapping or polishing the surface down.

To retain a resilient structure, a diversity of planes can be used along the edge of a laminated sheet, achieved by varying the orientation individual sheets prior to fusing them together. These edges are lapped and finally polished to size.

Finally, an interesting embodiment allows for a thin sheet of sapphire laminate to be bonded to a metal surface, such as steel. The glass backplates on Apple's iPhone 4S, for example, would benefit from such a design.

Apple's sapphire laminate patent credits Christopher D. Prest, Dale N. Memering, David A. Pakula, Richard Hung Minh Dinh, and Vincent Yan as its inventors.