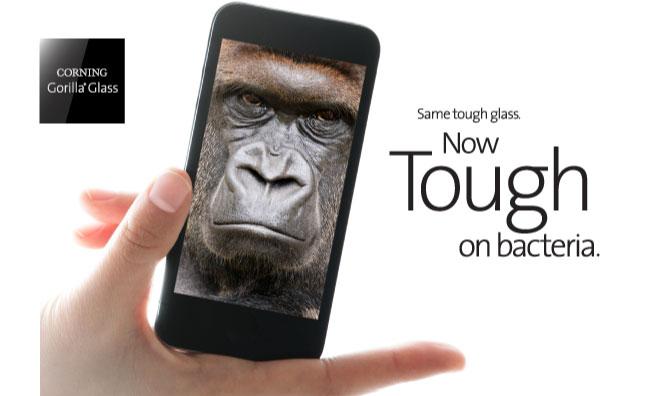

Mobile devices could be the next front in the war on germs thanks to a Corning innovation that infuses the company's popular Gorilla Glass with an antimicrobial agent without altering the glass's electrical or optical properties.

The new antimicrobial variant of New York-based Corning's ubiquitous cover glass is formulated using ionic silver and manufactured in what the glassmaker says is a precisely-controlled process designed to ensure the additive does not interfere with the glass's functionality. Word of Corning's antiseptic ambitions first surfaced last May.

According to Corning, Gorilla Glass's antimicrobial properties will not degrade over time, an attribute the company touts as an advantage over disinfectant wipes and films.

"Corning's Antimicrobial Gorilla Glass inhibits the growth of algae, mold, mildew, fungi, and bacteria because of its built-in antimicrobial property, which is intrinsic to the glass and effective for the lifetime of a device," said senior Corning executive James R. Steiner.

Corning continues to develop Gorilla Glass as competition from rival technologies, especially manufactured sapphire, begins to heat up. Sapphire --Â found most often in wristwatches --Â is the harder of the two materials and features more robust scratch resistance, while Gorilla Glass has been shown to be less prone to shattering.

Apple has made significant investments in sapphire, including a $578 million deal with GT Advanced Technologies to build and operate an Arizona facility to supply advanced sapphire material. Apple's iPhone 5s uses sapphire as a protective layer over the handset's Touch ID sensor as well as in the device's camera lens assembly, with many speculating that future iPhone models --Â or, perhaps, the company's rumored iWatch --Â could use sapphire in place of Gorilla Glass to protect the device's display.