A behind the scenes video from an Apple plant shows how the Daisy robot takes apart an iPhone to separate e-waste for recycling.

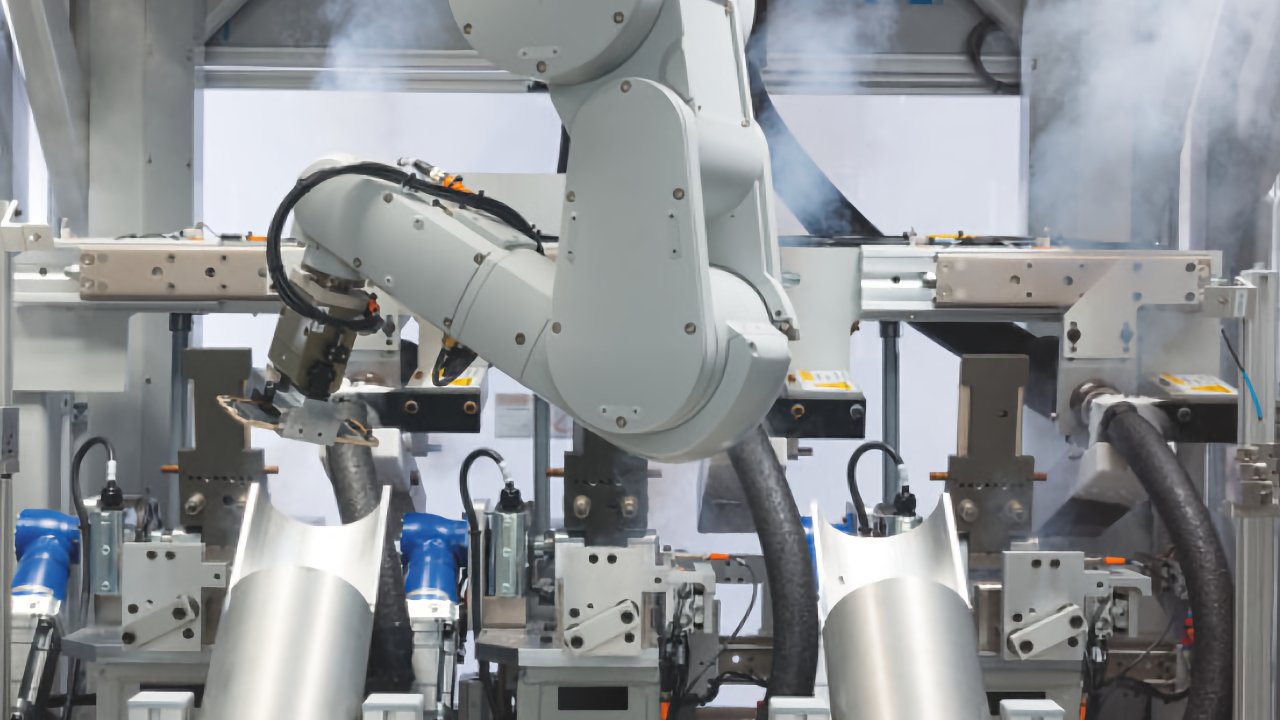

Apple first debuted a recycling robot in 2016 in the form of Liam, but then created a more advanced one named Daisy in 2018. Now Daisy is the subject of a short behind the scenes video showing the processes it goes through annually to precisely strip up to 1.2 million iPhones for parts.

I got to meet Daisy! Here is how Apple's iPhone recycling robot works pic.twitter.com/YNoXqcScDD

-- Sara Dietschy y (@saradietschy) April 20, 2022

YouTube technology reviewer Sara Dietschy presents the almost four-minute video and reports how Daisy is part of a whole e-waste recycling effort.

"There's a ton of different methods that basically separates metals from plastics from paper," she says. "But the thing with this is it doesn't separate everything with a great deal of accuracy."

In comparison, the four parts of Daisy precisely remove components, starting with the iPhone display. It then takes out the battery, then the screws.

In the final stage, all the components that Daisy has stripped out get put on a conveyor-like system for human workers to assess.

Separately, as part of its Earth Day 2022 efforts and Environmental Progress Report, Apple said that it has offered to license the patents relating to Daisy for researchers and firms developing their own disassembly processes.