An Apple patent application published Thursday confirms the company's continued interest in advanced force detection technology, dubbed 3D Touch in Apple parlance, with a novel back-sensing configuration that could lead to thinner handset designs.

Published by the U.S. Patent and Trademark Office, Apple's application for "Detecting backside force in a touch-screen device" details a method of integrating and calibrating force sensors to detect back-side user input.

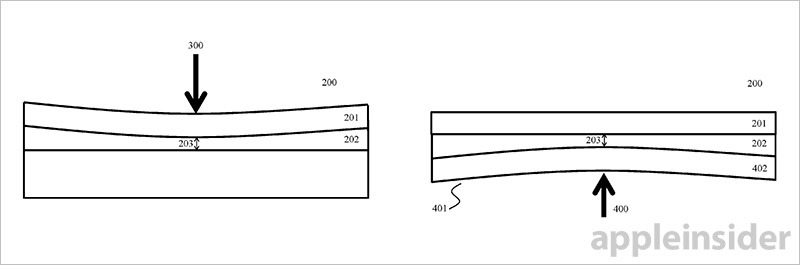

In concert with detecting back-side force input, the integrated sensor would be tasked with measuring potential strains during normal use that could lead to inaccurate front-side readings. Such a configuration would allow the implementation of exceedingly thin chassis designs prone to flexing during force press operations.

Current state-of-the-art technology, like 3D Touch, integrates a force sensing layer on, near or beneath a smartphone's display or cover glass. Apple's current solution detects force by measuring and mapping minute changes in capacitance between an iPhone's cover glass and a rigid metal sensor layer embedded in the backlight.

A separate multitouch capacitive sensor disposed above the display pulls double duty in 3D Touch by determining finger location during force gestures. Completing the system's major operating components is a haptic feedback module dubbed the Taptic Engine.

As noted by Apple in today's filing, users performing force gestures might unintentionally bend or otherwise apply excess pressure to the back of the device, causing the housing to deform. If a user's press is strong enough, or the device thin enough, this deformation could propagate to the force sensor, potentially leading to errant or false readings.

To protect against such scenarios, manufacturers can stiffen a smartphone's chassis by using a more rigid material or adding thickness to the rear housing. These solutions could add unwanted bulk to the handset's design, add cost to the manufacturing process and restrict implementation of rear-sensing apparatus, Apple notes. Indeed, the invention's successful operation hinges on detecting applied force through a device's internals.

Instead, the invention proposes leaving the housing without additional stiffening, or even reduce stiffness, and calibrate the force and touch sensors to generate an accurate map of applied force that includes back-side input. In some cases, the force sensor might be calibrated to account for internal structures like a battery pack or logic board.

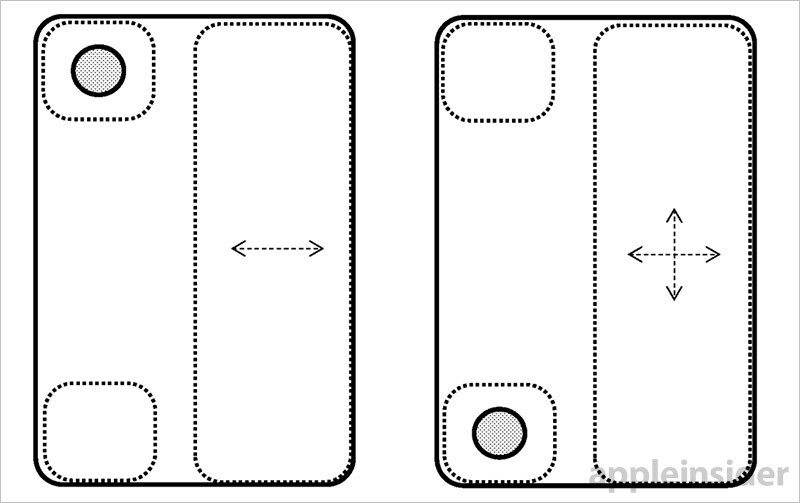

Since the force or strain sensor is designed only to detect non-localized changes in capacitance, it is hard pressed to distinguish forces applied to the top of the device from those applied to the bottom of the device or on both sides simultaneously. Therefore, like current iterations of 3D Touch, the system correlates force and touch input data to achieve a highly localized response in relation to front-side input. Extrapolating that technology out to include non-correlated events enabled back-side pressure tracking.

Specifically, measurements of force and measurements of touch input are matched to determine whether a given user interaction is meant to be front-side or back-side oriented. This is accomplished by determining whether touch contacts correspond to the location and intensity of applied force maps.

If a touch contact is within a predetermined threshold distance of an applied force, the event is deemed to be a front-side input. Conversely, touch and force readings that do not correlate with one another imply a force is likely being applied to the back of the device. The invention details more specific scenarios, as well as alternative embodiments designed to ensure the system is accurately translating user intent.

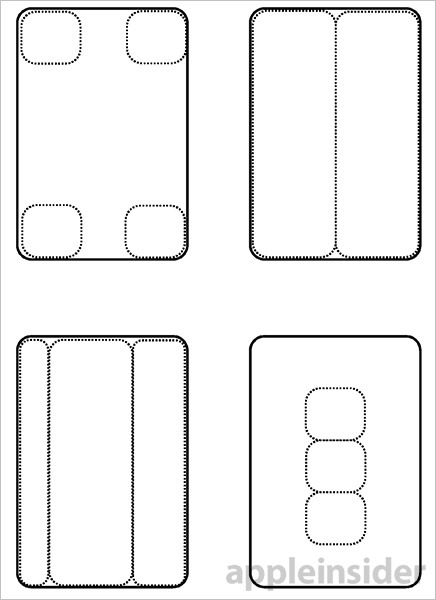

Using this information, the proposed solution can choose to ignore back-side input or trigger a host of specialized back-side force actions. Since it lacks a rear touch sensor, the system is not as granular as 3D Touch, meaning input is limited to larger regions or "zones."

Even so, back-side force input as described can offer a multitude of additional 3D Touch-style options, whether it be restricted to halves, quarters or slices of a device's rear housing. Further, these back-side segments might also support moving gestures like swipe actions, leading to a set of increasingly complex control alternatives.

Whether Apple intends to implement back-side force sensing in a future device remains unknown. 3D Touch is still in its early phases after seeing an introduction with iPhone 6s.

In current iOS versions, 3D Touch powers a handful of force sensitive controls including Peek and Pop, a user interface feature that provides linearly proportional software responses to increased finger pressure. Lightly pressing an interactive onscreen object like a hyperlink opens a new temporary Safari window, for example, allowing users to "peek" into its content. A harder press "pops" that floating UI pane into fullscreen view.

While many first- and third-party apps take advantage of the technology, users have been slow to adopt the UI tech Apple touted as "the next generation of multitouch." That will likely change with iPhone X, however, as the new home button-less flagship is heavily reliant on force gestures.

Apple's back-side force input patent application was first filed for in March 2017 and credits Golnaz Abdollahian and multitouch guru Wayne C. Westerman as its inventors.

Mikey Campbell

Mikey Campbell

-m.jpg)

Andrew Orr

Andrew Orr

Wesley Hilliard

Wesley Hilliard

Oliver Haslam

Oliver Haslam

Christine McKee

Christine McKee

Amber Neely

Amber Neely

11 Comments

Please Apple, get over this 'thinness' obsession. They are thin enough already. We want more battery life ok!

:'(

I see Wayne Westermam listed on the patent. I believe he cams to Apple from the Fingerworks acquisition. Not sure if he still works at the company. This got me thinking which acquisition has been a bigger deal for Apple - Fingerworks or PA Semi. Hmmm....toss up.