In the 9-page filing published for the first time this week, the Mac maker explains that carbon fiber reinforced plastic, also referred to as carbon fiber composites, provide a very strong, lightweight material for forming housings for electronic devices and portable computers.

The company describes in some detail how these composites are traditionally formed by laying sheets of carbon fiber material into a mold that is the shape of the desired product, which is then filled with thermosetting resin that is "cured" and cooled until the thermoplastic resin is below its glass transition temperature, thereby allowing the material to maintain the shape of the mold.

There are also some alternative methods to forming carbon fiber composites, though Apple takes issue with all of them because the methods produce composites that are almost always black in color with carbon fibers visible on the composite surface, which together threaten to dictate the aesthetic of products for which they're employed.

"In addition, the fibers (either as a unidirectional, woven, or nonwoven substrate) are typically variable in their construction and therefore are variable in their surface presentation," the company says. "As a result, the resulting carbon fiber composite can have cosmetic imperfections that reduce the aesthetic appearance of the molded article formed therefrom. Further, carbon fiber composites, often being black, provide a narrow range of surface appearance to the molded article and therefore may give a 'tired,' unexciting look."

Apple's fairly detailed and technical solution to the problem is described as such:

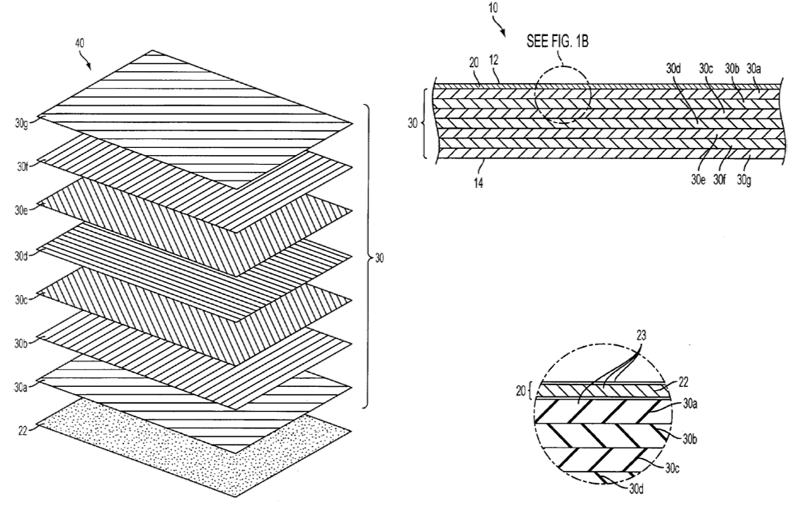

A composite laminate having an improved cosmetic surface is presented herein. The composite laminate includes a plurality of sheets of preimpregnated material, or prepreg, stacked one over another and a scrim layer provided on an exterior surface of the sheets of prepreg. The scrim layer and the sheets of prepreg form a composite laminate whereby the scrim layer constitutes an outer, exposed surface of the composite laminate. Each sheet of prepreg is made from fibers preimpregnated with resin, and the fibers of the prepreg may be substantially parallel or woven carbon fibers. The scrim layer may be a glass fiber or carbon fiber scrim, or veil, that has absorbed resin from the sheets of prepreg during a molding process. In another embodiment, the composite laminate includes a plurality of sheets of prepreg stacked one over another and first and second scrim layers provided on opposing exterior surfaces of the sheets of prepreg, whereby the sheets of prepreg are sandwiched between the first and second scrim layers. The first and second scrim layers constitute exposed surfaces of the composite laminate.

Enclosing a carbon fiber composite in a thin scrim made of glass fiber — which is less stiff than carbon fiber — would offer improved impact resistance over a similar composite laminate incorporating a carbon fiber scrim and would also hide the reinforcing fibers of the carbon fiber prepreg sheets, Apple claims.

"Since scrim absorbs resin of the composite, scrim takes on the cosmetic properties and color of resin. Also [...] scrim is very thin, and it is translucent, and the underlying fibers of composite are partially visible therethrough," the company explains in more detail. "The combination of resin and scrim forming scrim layer imparts a depth to surface of composite laminate, thereby providing an improved cosmetic surface of a molded article formed therefrom that is not only consistent in appearance, but is also aesthetically pleasing."

As such, Apple concludes that the "embodiments of the present invention described herein provide a designer with the opportunity to produce molded articles that have the advantageous properties of carbon fiber composites, without being limited to its black color or its imperfections in appearance."

Readers may recall that last November AppleInsider cited people familiar with Apple's portable computing plans who noted that the company has been looking into substituting carbon fiber parts for certain structural components of its notebook products that are currently cast from heavier aircraft-grade aluminum.

In particular, the Mac maker was said to be exploring the idea specifically for the MacBook Air by which it would replacing the Air's lower aluminum case, or bottom cover, with one constructed from carbon fiber.

The move would reportedly raise production costs but shave upwards of a 100 grams off the ultra-thin notebook, dropping its weight from a hair over 3 pounds (or 1363 grams) to 2.78 pounds (or 1263 grams). At the time, a pre-production unit showcasing the new part was said to be floating around in one of the company's labs, looking identical to the existing Air with the exception of the carbon fiber bottom, which, contrary to Apple's liking, appeared in the material's native black.

Sam Oliver

Sam Oliver

-m.jpg)

Christine McKee

Christine McKee

Charles Martin

Charles Martin

Mike Wuerthele

Mike Wuerthele

Marko Zivkovic

Marko Zivkovic

Malcolm Owen

Malcolm Owen

William Gallagher

William Gallagher

-m.jpg)

88 Comments

I like those machines with the carbon fiber bottom. The two tone look is stylish. But is shaving 100 grams off the current weight worth the expense?

No, no, no, no, no! I like the aluminum! Don't go back to anything that looks plasticky!

Every time a "better" material is used, it costs more, such are the facts of material technology.

Every time a "better" material is used, it costs more, such are the facts of material technology.

I don't know... Aluminum may be a cheaper material, but the machining process certainly isn't. Carbon fiber, like fiberglass, is a pretty simple process in terms of manufacturing.

This makes sense given that right after the first iPhone came out, Apple advertised for (and presumably hired) a really high end carbon fibre composite person.