Apple has shown off its Daisy robot for recycling iPhones before, but now it's become much faster by using brute force.

Daisy has been stripping old iPhones for parts for many years now, and is part of Apple's aim to end mining for resources. it was itself an update to a previous robot called Liam, which would originally dissemble an iPhone in 12 minutes.

Later versions of Liam got that down to 11 seconds, and according to TechCrunch, Daisy now strips an iPhone in 18 seconds. That's obviously slower than with Liam, but where the older machine could only dissemble the iPhone 6, Daisy can handle 29 different models.

"One metric ton of material recovered from Daisy prevents 2,000 metric tons of mining," said Sarah Chandler, Vice President of Environment and Supply Chain Innovation.

Despite the benefits, and in spite of its radically improved speed, Daisy's imposing 33-feet of robotics can strip up to 1.2 million iPhones a year — while an estimated 150 million smartphones were discarded in 2023. Apple has offered to license its Daisy patents for free to anyone that wants it, but so far not one single company has taken it up.

"I think we need to continue to do more and more with customer engagement," says Chandler. |That's why this isn't going to be Daisy's most productive day... she's running a little slower to accommodate [a facility tour]. But that's worth it. That's how we get the message out."

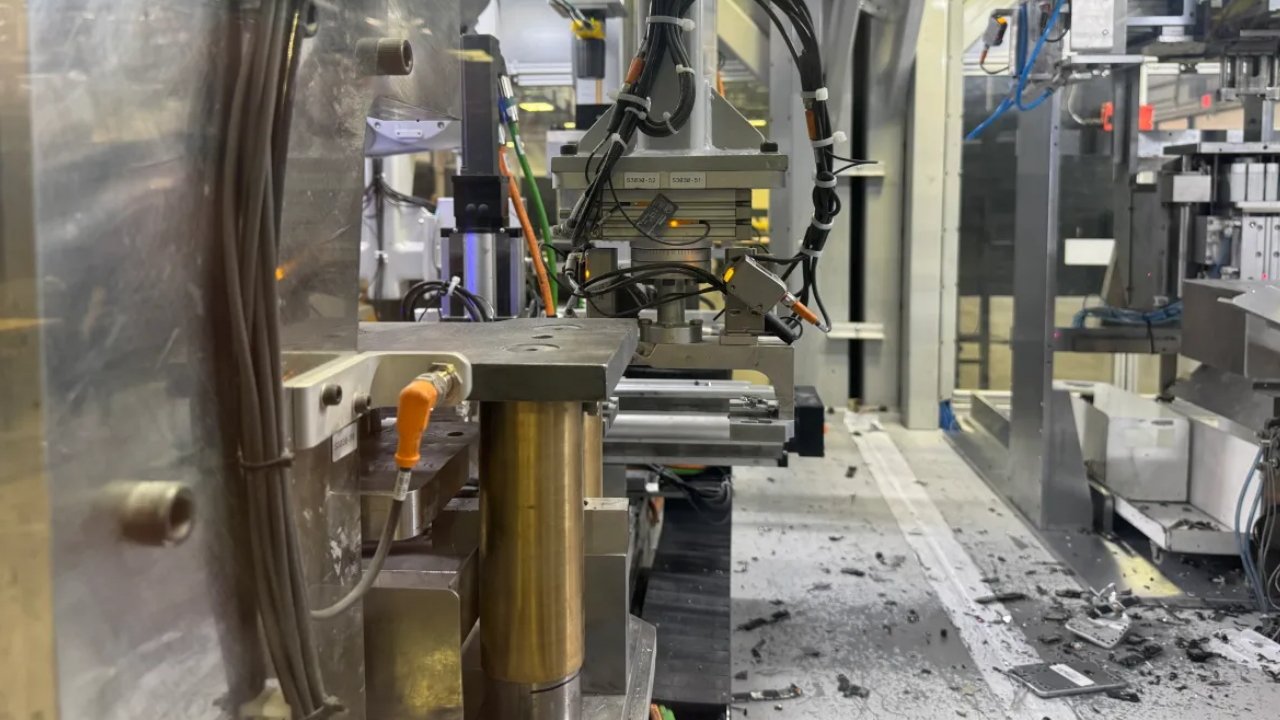

Brute force recycling

Previously, Apple's recycling robots used to grip the iPhone and quite painstakingly unscrewing and removing each component. Now those components are punched straight out of the device, ripping apart the iPhone for speed.

The process is done in a series of four stages, starting with bucketfuls of iPhones being dropped into a chute. Daisy puts each one on a conveyor belt, and uses machine learning to determine what specific model it is.

Next the display is peeled off, and each device is subjected to temperatures of -80 degrees Celsius (-112F), which makes adhesive in the batteries fail. Daisy then knocks that battery out, and the iPhone continues to the next stages.

Those end with components landing on a spinning surface, where a human being will sort them. Then boxed-up sets of components are sent out to e-waste companies.

Daisy is comprised of four sections, all housed within this one structure. (Photo: TechCrunch, Brian Heater)

Daisy is comprised of four sections, all housed within this one structure. (Photo: TechCrunch, Brian Heater)Recycling in Austin, Texas

While those e-waste firms are external, Apple says that it aims to do as much of the recycling in-house as it can.

"It's so important to do it internally," says Patrick Wieler, Recycling Innovation Engineer. "Every evolution taught what we can do with automation and gives us a big step forward."

"It's a constant dialogue," he continues. "We learn a ton from the automation team working on the new products, because they're always faced with their own unique set of challenges."

"We can build on their learning there and then vice versa with their teams," he says. "When we share how we were programming Daisy, it allows them to think about new approaches to the automation of new products."

Apple has two of the Daisy recycling robots, with one based in the Netherlands, and one in Austin. Chandler says being based in Austin has been particularly useful to her team.

"We've got strong, longstanding connections here," she says. "We've obviously got a lot of big campuses here, so we're able to do a bunch of recycling here."

"And it's been great for academic partnerships, too," continues Chandler. "We are able to get quite a few interns... we get a lot folks who want to explore robotics, recycling and material recovery."

Separately, Apple has been expanding its Austin campus, even a it shuts down others including a San Diego office. Some 121 people from that office were offered roles in Austin.

William Gallagher

William Gallagher

-m.jpg)

Christine McKee

Christine McKee

Amber Neely

Amber Neely

Andrew Orr

Andrew Orr

Sponsored Content

Sponsored Content

5 Comments

How much do these machines cost? Isn’t it as simple as building more of them? How many of the 150m discarded phones are iPhones? I’m guessing a minority, but what other company besides Apple is going to these lengths to recycle and reduce waste/mining? Does this fact get any consideration in the EU, which portrays itself as environmentally conscious?

amazing.

Funny we never hear about things like this from the knockoffs, the copycats, the chinese brands…some here like to imagine those others are leaders too, and yet we don’t see them actually leading the way, only following, with knockoff designs, knockoff materials, knockoff colors, even ads… How about instead of aping Apple commercials they actually pioneer closed-loop manufacturing and device recycling?