The U.S. Patent and Trademark Office on Thursday published an Apple patent application for a method of constructing a camera lens actuator that uses a single artificial muscle structure rather than traditional motors to control focus and aperture size.

According to Apple's aptly named "Artificial muscle camera lens actuator" filing, suggestions to apply artificial muscle technology to camera autofocus actuators have been floating around for some time, but the electro-active polymer (EAP) materials on which the tech is based were not suitable for mass manufacture until recently.

With the proliferation of haptic feedback features in devices like remotes for video game consoles, the appropriate engineering cogs are in place to mass produce the materials, though an exact production design tailored for camera autofocus actuators has yet to be vetted.

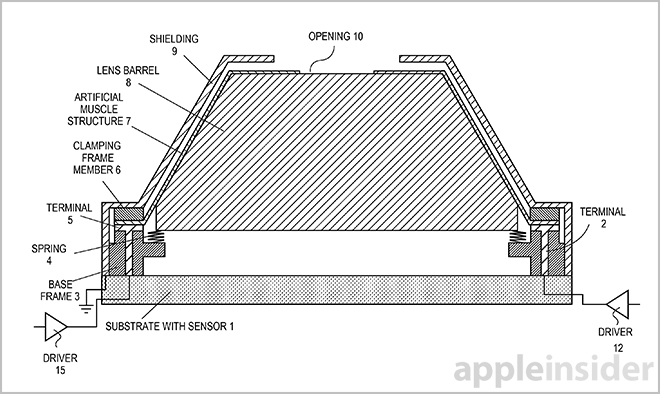

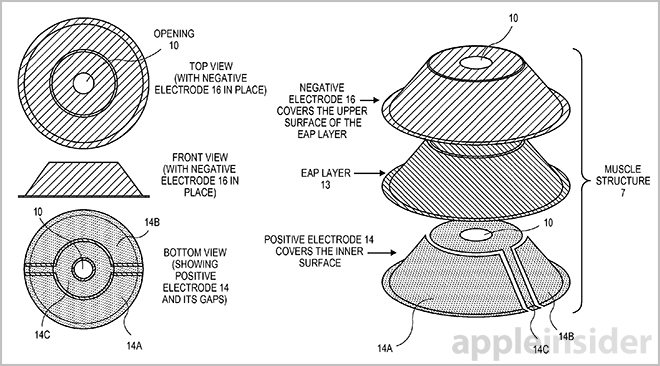

To that end, Apple proposes a micro electromechanical system (MEMS) design using an EAP layer having a frusto-conical shape as seen in the illustration below. Situated at the tip of the artificial muscle structure is an opening to be used as the camera's aperture, which can be variably displaced via complementary electrodes attached or screen printed onto the front and back of the layer.

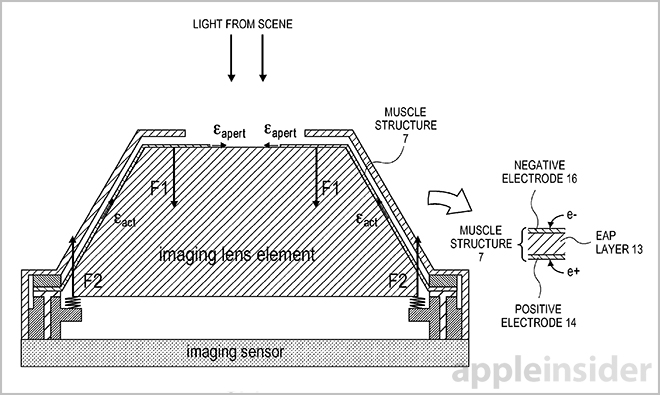

The EAP layer itself can include one or more layers of polymer material sandwiched together between the two flexible electrodes. When voltage is applied, the potential differential generates an electrical field that subsequently activates conductive particles in the polymer layers to create a substantial force that results in elongation of the structure.

The example above shows the force exerting itself in a rearward direction with potential difference on opposing surfaces depicted by "e+" on the positive electrode and "e-" on the negative electrode. A spring attached to the lens barrel or lens holder creates a loaded opposing force that can overcome the first force, thereby facilitating forward and backward movement along the imaging axis.

Taking a closer look at the artificial muscle structure, the image below illustrates how both displacement and variable aperture control can be achieved in a single mechanism. The formation places a positive electrode on the inside of the EAP layer with a gap running from its base to the tip, splitting it into two separate actuation segments that control lens barrel movement.

A third electrode is placed within the created gap so that an aperture created in the EAP material can be variably controlled by changing the electrode's potential independently of the two actuation segments. Alternatively, aperture size may be controlled by changing the potentials on the two actuation segments relative to the third electrode.

Apple notes an artificial muscle structure is advantageous because it can carry relatively large optics and consumes extremely low levels of power.

Whether Apple will apply the technology to a future iOS device remains unclear. As portables like the iPhone become increasingly thin with each successive generation, however, the company may soon find a need to look in the direction of alternative solutions to the rather bulky voice coil motor used in current models.

Apple's artificial muscle camera lens actuator patent application was first filed for in August of 2013 and credits Aurelien R. Hubert, Douglas S. Brodie, Iain A. McAllister and Jeffrey N. Gleason as its inventors.

Mikey Campbell

Mikey Campbell

-m.jpg)

Charles Martin

Charles Martin

Christine McKee

Christine McKee

Wesley Hilliard

Wesley Hilliard

Malcolm Owen

Malcolm Owen

Andrew Orr

Andrew Orr

William Gallagher

William Gallagher

Sponsored Content

Sponsored Content

67 Comments

Many, Many years ago I submitted a patent for a device that would amplify radio waves, as part of that, it used interferometry to split a laser and cancel out other "non information" on the carrier signal. I also designed a "ferro fluid lens" system -- which showed up in someone else's patent about 10 years later (but it was kind of an obvious application and I doubt it was from what I submitted).

The sad thing is that I sent this design to "Invention Submission Corporation" -- it's probably changed its name many, many times by now. That's a company that has ZERO engineers on hand to evaluate, but a lot of salespeople who say; "We think this has a lot of potential, so if you send in a few thousand more dollars, we can get to work on developing it further…" Me; "You mean you don't have some people who can just look at what is being designed and realize that I've got 5 unique designs in here, and it would be really great to have an analog system to filter out nearly all noise on any signal, and then convert that to digital without having to boost the signal?" Idiots!

Instead of a very complex lens system to focus with a "muscle", merely having a small current in a series of ferro-fluid capillaries to change curvature in a microsecond without moving parts would make this incredibly simple.

Sorry, I have to mope on occasion about having a mind that can solve things, but not a life where I can express any of those talents.

It's good to see someone having a chance to innovate and find applications for new materials and processes -- and that's why it's fun to track Apple.

[quote name="Fake_William_Shatner" url="/t/180805/apple-invents-iphone-camera-lens-actuator-made-of-artificial-muscle#post_2552644"]Many, Many years ago I submitted a patent for a device that would amplify radio waves, as part of that, it used interferometry to split a laser and cancel out other "non information" on the carrier signal. I also designed a "ferro fluid lens" system -- which showed up in someone else's patent about 10 years later (but it was kind of an obvious application and I doubt it was from what I submitted). The sad thing is that I sent this design to "Invention Submission Corporation" -- it's probably changed its name many, many times by now. That's a company that has ZERO engineers on hand to evaluate, but a lot of salespeople who say; "We think this has a lot of potential, so if you send in a few thousand more dollars, we can get to work on developing it further…" Me; "You mean you don't have some people who can just look at what is being designed and realize that I've got 5 unique designs in here, and it would be really great to have an analog system to filter out nearly all noise on any signal, and then convert that to digital without having to boost the signal?" Idiots! Instead of a very complex lens system to focus with a "muscle", merely having a small current in a series of ferro-fluid capillaries to change curvature in a microsecond without moving parts would make this incredibly simple. Sorry, I have to mope on occasion about having a mind that can solve things, but not a life where I can express any of those talents. It's good to see someone having a chance to innovate and find applications for new materials and processes -- and that's why it's fun to track Apple. [/quote] Your patent idea reminded me of the oil lenses of the electric binoculars used in Frank Herbert's science-fiction masterpiece, Dune (1963). Of course, Herbert never had to engineer his descriptions to make sure they actually worked. I doubt there is any technology available that could make an ornithopter function.

This artificial muscle sounds amazing, and gross. Here's hoping they give the first Terminators rubber skin, so we can spot them easily.

[quote name="Crowley" url="/t/180805/apple-invents-iphone-camera-lens-actuator-made-of-artificial-muscle#post_2552655"]This artificial muscle sounds amazing, and gross. Here's hoping they give the first Terminators rubber skin, so we can spot them easily. [/quote] No actual biological material is used.

Interesting design. I wonder why they prefer to cover the entire circumference of the lens cone with this material rather than use several supporting members that can be independently tuned. I haven't messed with these actuators, but it seems like there could be some manufacturing variability on a piece with a large surface area, causing the lens to move laterally off the axis, and/or tilt, while multiple bits could be monitored and calibrated on the fly with software to keep it all collimated.

At any rate, this is a very cool use of the technology -- I really like the aperture bit, as that removes a ton of moving parts and will provide wonderful blur outside the depth of field since there are no blades/intersections.