Apple is still working to perfect methods of manufacturing Liquidmetal parts, according to a new patent application published Thursday by the U.S. Patent and Trademark Office, with the company moving on to processes for melting the unique metal alloy and feeding it to casting and processing equipment.

The application, entitled "Methods of melting and introducing amorphous alloy feedstock for casting and processing," shows a number of ways in which amorphous alloys like Liquidmetal can be melted and injected into manufacturing equipment. It was filed in May of this year.

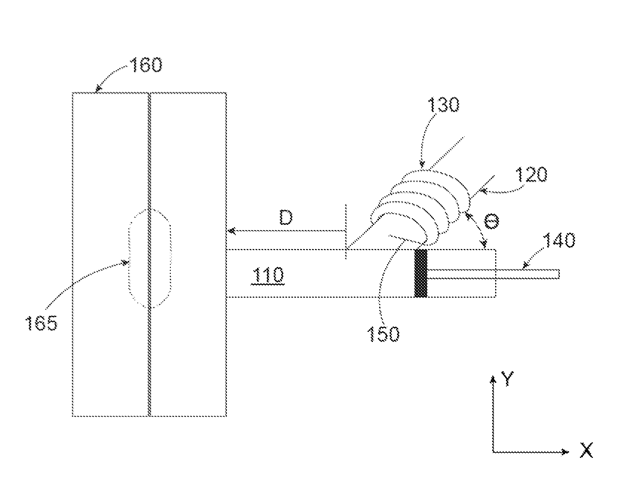

Apple's methods simplify the containment and pouring system necessary to transfer molten alloys. One method adds an additional "branch" to a tradition cold chamber, which contains the metal using water-cooled "fingers" containing a non-wetting surface — surface tension prevents the metal from moving until the fingers are retracted.

A second method uses a system not unlike a traditional hot glue gun, holding a solid piece of feedstock in place by a constriction in the feed tube. The feedstock is melted at the constriction point, then flows into the cold sleeve.

Apple says that parts formed with these methods have nearly endless application in consumer electronics, from internal parts with dimensions measured in millimeters to full outer casings. The applicaiton specifically mentions mobile phones, portable music players, streaming devices, laptop and desktop computers, and watches.

Though Apple's latest iPhone 6 models and the Apple Watch are not known to contain Liquidmetal parts — Â the iPhone 6 features an outer case made of aluminum, while the Apple Watch is available in stainless steel, aluminum, and 18-karat gold — Â it is possible that some internal components have been fabricated from the material.

Apple credits Theodore A. Waniuk, Joseph Stevick, Sean O'Keeffe, Dermot J. Stratton, Joseph C. Poole, Matthew S. Scott, and Christopher D. Prest with the invention of U.S. Patent Application No. 0140251568. As usual, the application is assigned jointly to Apple and Crucible Intellectual Property, a subsidiary of Liquidmetal's parent company that exclusively handles Apple's license.

Sam Oliver

Sam Oliver

Malcolm Owen

Malcolm Owen

Amber Neely

Amber Neely

Christine McKee

Christine McKee

Chip Loder

Chip Loder

Marko Zivkovic

Marko Zivkovic

66 Comments

I´m sure Apple have perfected Liquidmetal production a long time ago.

But why not milk the market with aluminium products for a while longer? I bet we´ll see at least 5-6 product cycles with the same old before they feel pressured enough to start pushing new materials.

It´s all about making it better than the competition. No need to push too far ahead when you can incrementally improve your products.

Liquidmetal Sapphire iPhone 6S (the "S" is for Sapphire)

As I've said all along, Sapphire in the 6S and Liquidmetal in the 7. That said, I was totally wrong about liquidmetal in the ?Watch. I would have sworn it was going to be there in Version 1. Then again, I thought the watch would be about 1/3 the thickness of the one they introduced, so I was wrong on both accounts. Considering the iPhone 7 will be coming out in two years (note how the 7 is an upside down "L" btw), I have to think that ?Watch 3 will probably be much slimmer than now and possibly also contain a lqmt body, at least in one iteration. Unfortunately for us investors in LQMT that means another LOOONG two more years before the stock jumps. Expecting it to trade in the .16 to .30 range for the whole time...

Looking at Liquidmetal's financials, it looks like Swatch has exclusive rights to use Liquidmetal in watches, just like Apple's agreement for exclusive rights in electronic devices.

i think apple is already using liquidmetal alloys in its watch, the 'series 7000 aluminium alloy' is 60% stronger and 'very light'. the 'custom gold alloy' is 2 times harder than standard 18kt alloys. the 'custom stainless steel 316L alloy' is 40% harder than 316L stainless alloys. apple also uses terms 'cold forged' and ' tempered' too describe its custom stainless alloy, you can also use those words to describe BMG or amorphous alloys. all those terms sounds like different liquidmetal alloys to me, most likely they are all injection moulded, same mould just different alloys cold forged with the above patent.