An analysis of parts found inside Samsung's new Galaxy S4 has concluded the flagship smartphone is more costly to build than Apple's iPhone 5, with a price tag of $237 for the 16-gigabyte model.

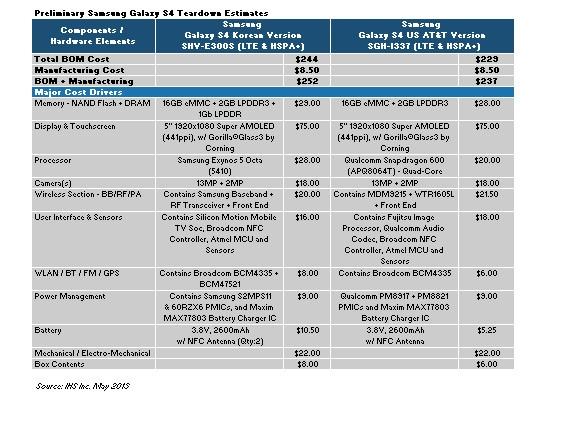

The analysis conducted by IHS iSuppli found a great deal of difference between the U.S. and Korean versions of the Galaxy S4. Their estimates found that the AT&T version is cheaper, at $237, than the $252 model built for Korea, when the cost of parts and manufacturing are combined.

The biggest difference in cost comes from the processor: The AT&T model features a Qualcomm Snapdragon 600 quad-core CPU that is estimated at $20, while the Korean model has a $28 Samsung Exynos 5 Octa.

The costs compare to an estimated total bill of $207 for parts and manufacturing of Apple's 16-gigabyte iPhone 5. The two competing handsets are priced comparably with carrier contract subsidies, suggesting that Apple makes greater profit margins on the iPhone 5 than Samsung does with the Galaxy S4.

Of course, these estimated values do not include the money invested in research and development of both hardware and software. The teardowns represent only the component prices and costs to assemble the devices.

The most expensive part of the Galaxy S4 is the 5-inch touchscreen display, which is estimated to have a $75 price tag. The Super AMOLED screen features a 441-pixel-per-inch density and is protected by Corning's Gorilla Glass 3.

Other part estimates include the 13-megapixel rear and 2-megapixel front cameras ($18), 16 gigabytes of storage ($28), power management components ($9), and various sensors ($18).

The total bill of materials cost for the U.S. AT&T version is $229, while the Korean version costs $244. Both have an estimated manufacturing cost of $8.50, which brings them to their respective final costs.

AppleInsider Staff

AppleInsider Staff

Brian Patterson

Brian Patterson

Charles Martin

Charles Martin

Malcolm Owen

Malcolm Owen

William Gallagher

William Gallagher

Christine McKee

Christine McKee

Marko Zivkovic

Marko Zivkovic

43 Comments

Interesting. I wonder how accurate the pricing for parts is, especially considering how Apple has such a terrific supply chain, where they can pretty much dictate what they're willing to pay...

What a hilarious comparison. Build materials and manufacturing complexity aren't even taken into account. All that is compared are the internals of a hardware product that was released 6 months ago to one released TODAY, and concluding that the newer components cost more. Wow, my mind is blown.

1) This is iSuppli. 2) Even if we believe iSuppli has a [I]decent[/I] idea of Apple and Samsung's BoMs there would be enough margin for error to show that they'll all pretty much the same. 3) The only think I think we can say for certain by looking at this figures is that the Korean S4 costs a little more than the US AT&T S4.

"Of course, these estimated values do not include the money invested in research and development of both hardware and software. The teardowns represent only the component prices and costs to assemble the devices." Because we all know how little Samsung spends on R&D. They've already saved billions copying the original iPhone design...

Interesting. I wonder how accurate the pricing for parts is, especially considering how Apple has such a terrific supply chain, where they can pretty much dictate what they're willing to pay...

Let me put this way, iSupply pricing is completely wrong, it is a guess at best and I am not even sure how they come up with their pricing. In some cases I know the market pricing of parts and their pricing has never been right on they are either high or low and I am not talking about a small amount, ti seen their spreads very as much as 20%.

They my come close in the total price is some guesses are low and other are high so it averages out. Also with Samsung, they are assume they pay market pricing for part they buy from other Samsung business, that may not always be true.