The A16 Bionic chip found in the iPhone 14 Pro models costs $110 to manufacture, which is 2.4 times more than the A15 found in the iPhone 13 series and in the iPhone 14.

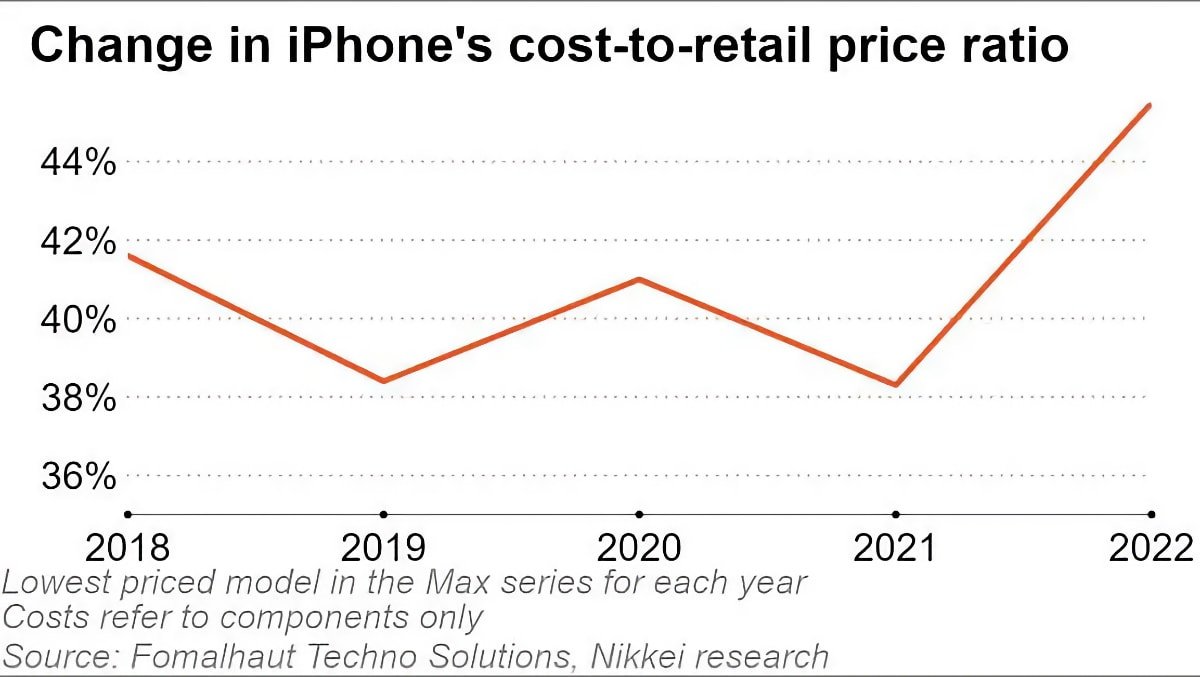

Nikkei Asia did a teardown of three models in the iPhone 14 series, examining components such as the processor and camera parts. The media company says the new series's production costs are 20% higher than the previous iPhone generation.

In terms of parts, calculations suggest production of the iPhone 14 Pro Max cost Apple $501 in parts, up over $60 from the iPhone 13 Pro Max. The firm calls this a steep production cost, saying parts prices for Max models have ranged between $400 and $450 since the debut of the iPhone XS Max in 2018.

The higher production cost is reportedly due to the A16 Bionic chips in the iPhone 14 Pro models. The chip costs $110, over 2.4 times more than the A15 in the iPhone 13 Pro Max.

The A16 Bionic uses a 4-nanometer process from chip supplier TSMC, while the A15 uses a 5-nanometer process. New camera components in the iPhone 14, including Sony's CMOS image sensor, are 30% larger than previous models and cost 50% higher at $15.

Parts for the iPhone 14 primarily come from US suppliers, accounting for 32.4% of costs, up 10% from the iPhone 13. However, South Korea was the top supplier in 2021 and saw its share of manufacturing drop by over five points, down to 24.8%.

The report also claims that since Apple raised iPhone prices in some countries such as Japan and Australia, but not in the US and other markets, higher production costs resulted in lower profits for the company.

But the more likely explanation is foreign exchange rates. The US dollar has been strong in 2022 compared to other currencies, meaning that imports into the country are cheaper for Americans to buy.

Fomalhaut Techno Solutions, a research company based in Tokyo, Japan, helped Nikkei examine the devices.

Andrew Orr

Andrew Orr

-m.jpg)

Wesley Hilliard

Wesley Hilliard

Oliver Haslam

Oliver Haslam

Christine McKee

Christine McKee

Amber Neely

Amber Neely

Sponsored Content

Sponsored Content

15 Comments

I can believe the total BOM cost of about $500. Maybe. It's your basic MSRP divided by 2 to 3, depending on how much you believe the soft costs are.

The headliner of an A16 SoC costing $110? I call BS on it. Nobody knows. Heck, I bet TSMC and Apple don't even really "know". It's a rather circular contracting arrangement of pre-paying, fixed-priced unit costs, technology funding, so on and so forth. How they determine $/SoC is going to vary with accounting assumptions. At $110, the SoC is 25% of the cost of an iPPM. Sounds crazy. If it was $80, easier to believe.

Another Nikkei insider trading Apple hit piece

so A15 costs $46

but A16 costs $110

and Apple is like OK cool?

people need to stop being dumb and believe everything on internet

Claiming to know the cost of the A16 or any other contract-manufacture chip without an inside source is, frankly, rubbish. Bring me die sizes and gate counts and I can make an informed guess. Moving to 4nm is a 2-edged sword for costs - reducing the overall die size would improve yields and reduce costs, unless other problems with the new process were suppressing yields, and there’s no mention of that here.

I would have thought a smaller process allowing more SOCs on the die would help reduce costs?

https://www.cnbc.com/amp/2022/10/07/amd-shares-fall-more-than-7percent-on-weak-outlook.html

TSMC may need to be more appreciative