Apple has been researching how to make an iPhone chassis that looks as good, and feels as smooth, as its current ones, but which can stand up to more wear and tear.

It's almost as if Apple forgets that it — and other firms — sell cases for the iPhone. The company has now been granted a patent for "Spatial Composites," which turns out to mean embedding metal or ceramic with a chassis for scratch resistance.

"[Mobile] phones, watches, and tablet computers, can experience contact with various surfaces that leads to marring, or abrasion, of the surface of the device," says Apple. "[Regular housing] materials for such devices may have different combinations of properties relating to strength, appearance, abrasion resistance, electromagnetic shielding, and the like."

So as Apple notes, different materials used in an iPhone chassis come with different benefits — and problems.

"[For instance,] metal housings may be particularly resistant to dents, scratches or breakage," it continues, "but may interfere with radio signals entering or emanating from the device."

"Ceramic housings may be scratch resistant and transparent to radio signals, but may be brittle," says Apple. "Plastic housings may be transparent to radio signals and fairly strong, but may be prone to scratches or dents."

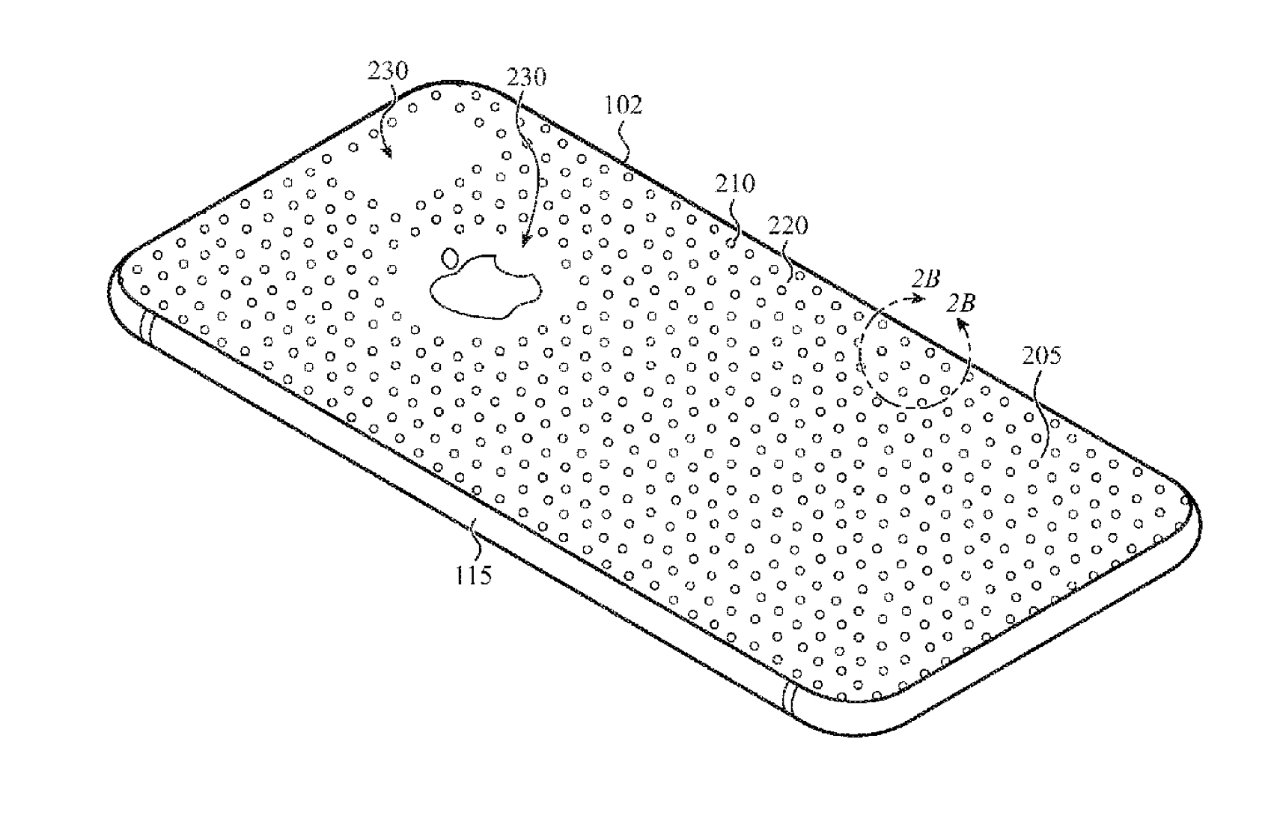

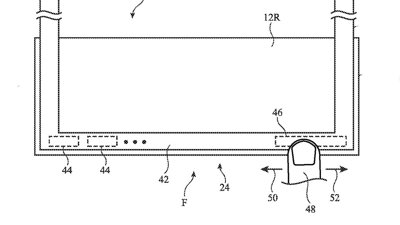

Detail from the patent showing rows of "abrasion-resistant" members - but they would be a lot closer together than this suggests

Detail from the patent showing rows of "abrasion-resistant" members - but they would be a lot closer together than this suggestsWhen Apple lays it all out like this, the company's proposed solution is obvious — use more than one material for the chassis.

However, of course it's not that simple and the whole patent is concerned with just what materials to mix, and how to do it.

"A housing of an electronic device" has to get "abrasion-resistant members at least partly embedded in the substrate [chassis material] and extending beyond the external surface."

"The abrasion-resistant members may be formed from metal or ceramic," says Apple. "The substrate comprises a moldable matrix. The abrasion-resistant members are harder than the moldable matrix."

Apple's patent includes drawings showing different shapes of "abrasion-resistant members," each with different benefits but the same overall aim. It also includes a drawing showing these members dotted over the back of an iPhone.

It's only an illustrative drawing, however. While it aims to show that the members will be arranged throughout the chassis, what it doesn't reveal is that the spacing between them is only between 10 and 100 microns.

The patent is credited to three inventors, including Christopher D. Preset. His previous related work includes the use of glass ceramic components in a MagSafe system that would transmit data as well as power.

William Gallagher

William Gallagher

-xl-m.jpg)

-m.jpg)

Amber Neely

Amber Neely

Malcolm Owen

Malcolm Owen

Mike Wuerthele

Mike Wuerthele

Thomas Sibilly

Thomas Sibilly

12 Comments

Apple's efforts are all about abrasion resistance. That's not at all the same as impact resistance. Cases will still be desirable.

Do current iPhones really need cases? I am caseless since the iPhone X and never had any issues. All scratches are so flat that they are only noticeable when you hold your iPhone directly beneath a light - but you can't notice them during the daily usage. Especially the 14 Pro currently is quite durable already.

Looking at Apples' revenue from accessories (including cases) I find this hard to believe. Add to this revenue from third-party certification, and that's a sizeable chunk of dough Apple is cutting with its own hands.

I'll always use a case, if not for protection, to make it less slippery.