A teardown has proven that Apple has used a new metal battery casing in the iPhone 16 Pro, with the model also benefiting from chassis changes that will help thermally manage the device's internals.

An inevitable part of the iPhone launch is the teardown, and the iPhone 16 generation is no different. Shortly after its release, the iPhone 16 Pro has been taken apart and inspected internally, revealing changes to Apple's design.

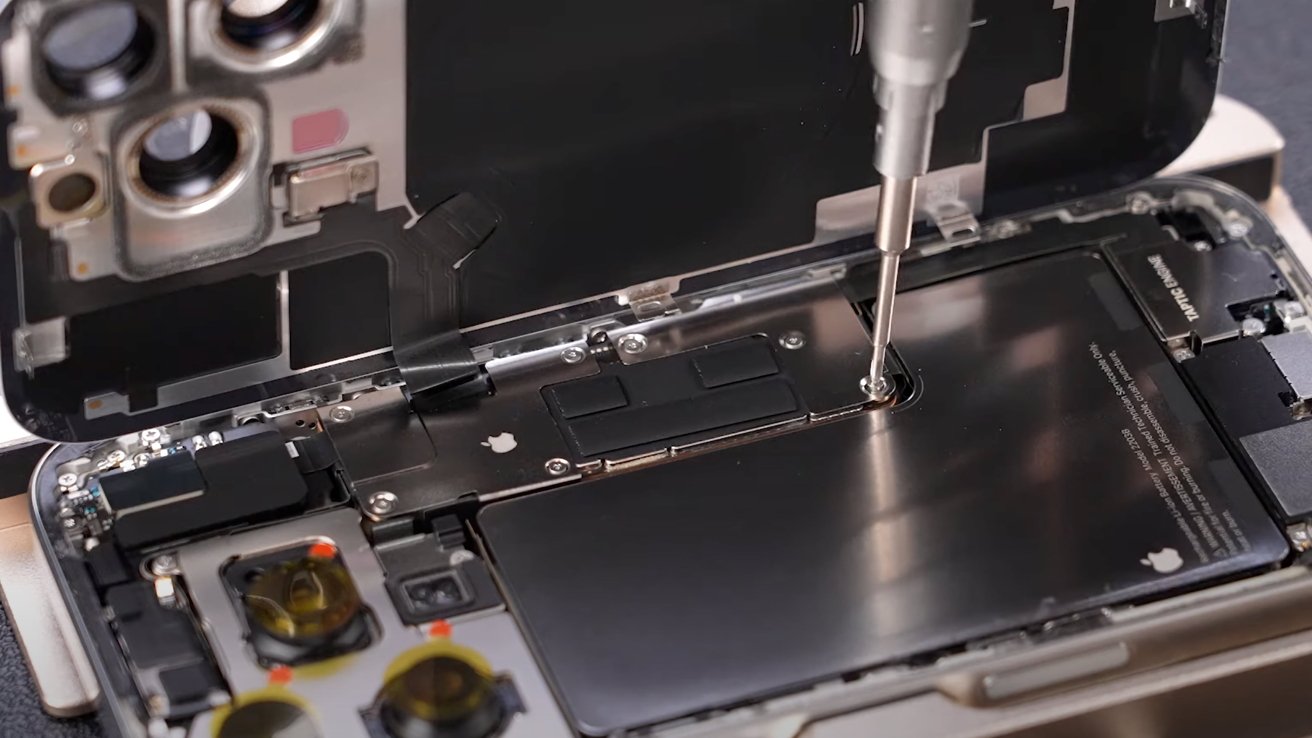

The teardown by Rewa Technology posted to YouTube involves a fairly standard disassembly of the iPhone 16 Pro. After heating the rear and separating the glass backing, the engineer had access to the internals as normal.

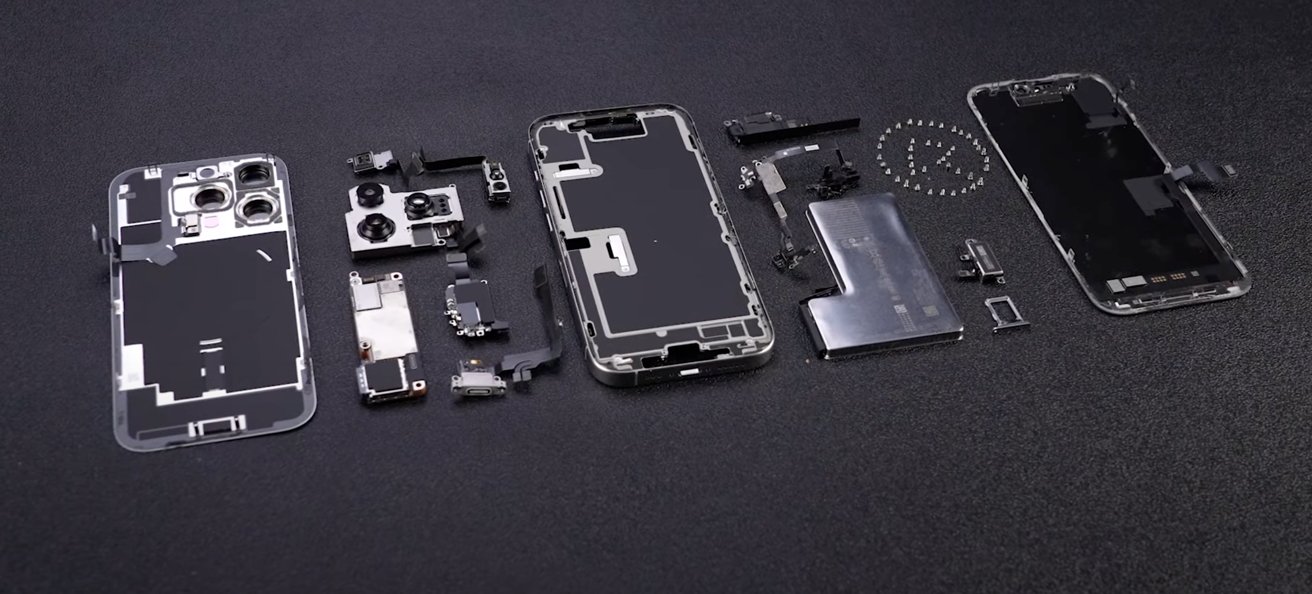

The first change spotted was the battery, which, just as rumored, has a shiny steel casing which is affixed with adhesive pads. This differs from the previous battery casings, which could help enhance heat dissipation compared to previous generations.

Curiously, the video claims the metal battery enclosure is limited only to the iPhone 16 Pro model.

The TrueDepth camera assembly is similar in construction to the iPhone 15 Pro's version, except it is smaller due to differently arranged cables. The rear camera assembly is larger, in part because of the bigger elements for the telephoto camera.

The motherboard used inside the iPhone 16 Pro is also smaller than its predecessor, with a new and more densely packed arrangement. A protection cover is larger in the new model, which may also help with heat dissipation.

The display is shown to be physically larger than the old model, though also having thinner bezels and a smaller screen frame. The Camera Control button, new to the casing, is a non-removable element laser welded to the chassis.

With all components removed, the new chassis layout is revealed. There's a new graphite-clad aluminum substructure, which again could assist with thermals as well as rigidity.

Malcolm Owen

Malcolm Owen

-m.jpg)

Amber Neely

Amber Neely

Mike Wuerthele

Mike Wuerthele

William Gallagher

William Gallagher

Andrew Orr

Andrew Orr

Wesley Hilliard

Wesley Hilliard

7 Comments

Does this mean it is also easier to disassemble or harder than the 15 Pro models?

I love how Apple designs the inside of their products to look as good as the outside. A great feat of proper engineering and just shows the great lengths Apple goes when designing its products, even if it's something most customers will never see.

Was it stainless or simply steel? Stainless is much more expensive and less thermally conductive than standard steel, and both are heavier less thermally conductive than aluminum. I wonder if the real reason is safety in case of a thermal runaway by the battery. In any case (pun intended,) how much heat is generated by the battery vs other components? And if we're worried about heat dissipation, why not address the elephant in the case - the glass back with a foam pad on it. Both of these will do far more to inhibit heat dissipation than the battery case.

Edit: it's possible that battery heating became an issue with the faster wireless charging. A metal case has significant costs both in terms of weight and cost so it's not something they would have done without a good reason.