While Apple has yet to employ the unique amorphous alloy known as Liquidmetal in any of its products in a meaningful way, a newly granted patent details a way to mass produce the material in thin sheets.

The method was revealed in an invention made public this week by the U.S. Patent and Trademark Office, and discovered by MacDailyNews, that was originally filed by Crucible Intellectual Property, LLC. That's the name of a special-purpose subsidiary wholly owned by Liquidmetal, maker of an amorphous metal alloy with a unique atomic structure.

Apple currently has an exclusive agreement with Liquidmetal through early 2014 to use the material in consumer electronics, though to date it was only used briefly to build SIM ejector tools for the iPhone and iPad. It's been said that the alloy is too expensive to be mass produced for a main design, though small amounts can be used for operational parts such as hinges or brackets.

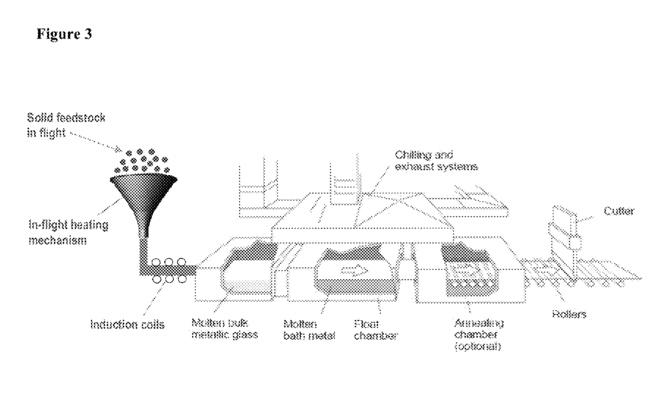

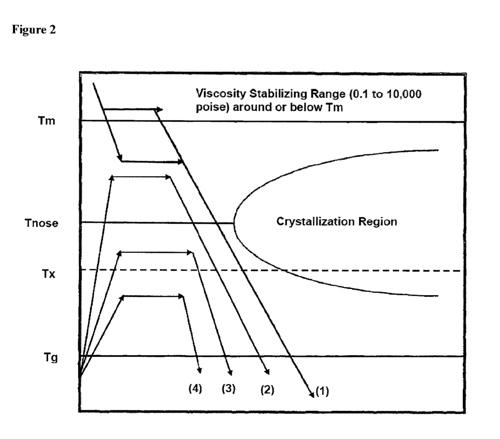

But the Liquidmetal patent, entitled "Bulk Amorphous Alloy Sheet Forming Processes," describes creating sheets of the alloy by using a float glass process. That's the same way that window glass is also produced in bulk.

The invention describes a molten sheet of bulk metallic glass traveling through a cooled conveyer. That sheet would then be cooled to form a "bulk solidifying amorphous alloy sheet."

By using the float glass process, a float plant could operate nonstop for between 10 and 15 years, the patent claims. This would allow it to make as much as 6,000 kilometers of bulk metallic glass per year sized up to 3 meters wide and up to 15 millimeters thick.

The names credited with the invention are split between employees of Apple and Liquidmetal. Christopher D. Prest and Joseph C. Poole work at apple, while Joseph Stevick, Theodore Andrew Waniuk and Quoc Tran Pham are all Liquidmetal employees.

The newly awarded patent was first filed with the USPTO by Liquidmetal's subsidiary in May of 2012.

Rumors have claimed for years that Apple will leverage its exclusive agreement with Liquidmetal and use the material in an upcoming product like a next-generation iPhone or even MacBook casing. But one of the inventors of the material said in a 2012 interview that he believes the utilization of Liquidmetal as a primary material for the frame of a device would be years away, allowing time for the technology to be matured and perfected.

Apple's exclusive arrangement with Liquidmetal was first discovered by AppleInsider in 2010. The agreement gives Apple "a perpetual, worldwide, fully-paid, exclusive license to commercial such intellectual property in the field of electronic products in exchange for a license fee."

AppleInsider Staff

AppleInsider Staff

-m.jpg)

Charles Martin

Charles Martin

Christine McKee

Christine McKee

Wesley Hilliard

Wesley Hilliard

Malcolm Owen

Malcolm Owen

Andrew Orr

Andrew Orr

William Gallagher

William Gallagher

Sponsored Content

Sponsored Content

57 Comments

Before everyone says it, there is no way that the invention of this process would lead to BGR's idea that the iPhone 5s will be made out of liquid metal.

Apple filed 25 patents watch this http://www.google.co.in/url?q=http://www.youtube.com/watch%3Fv%3DgOqeqpt8ZGA&sa=U&ei=N93mUZuGDsPnrAfuxYC4DQ&ved=0CB4QtwIwAQ&usg=AFQjCNHm26e0VTspbz7CgKzwc5JN5JmLEQ

Just thinking aloud...

The whole point of LM is the fact that it can be injection molded into shapes, instead of having to be milled.

The article talks about a process to make LM sheets, which is likely not the target shape, but perhaps could be used as raw material for such molds.

[quote name="Selva Raj" url="/t/158526/patent-reveals-apples-process-for-mass-producing-liquidmetal-alloy#post_2363174"]Apple filed 25 patents watch this http://www.google.co.in/url?q=http://www.youtube.com/watch%3Fv%3DgOqeqpt8ZGA&sa=U&ei=N93mUZuGDsPnrAfuxYC4DQ&ved=0CB4QtwIwAQ&usg=AFQjCNHm26e0VTspbz7CgKzwc5JN5JmLEQ[/quote] Thanks for the link. He repeatedly emphasized 'injection molding'. So I'm not seeing any significant barrier to the possibility of this being an alternative to a product machined from a block of aluminum in certain Apple products.

[quote name="KDarling" url="/t/158526/patent-reveals-apples-process-for-mass-producing-liquidmetal-alloy#post_2363179"]Just thinking aloud... The whole point of LM is the fact that it can be injection molded into shapes, instead of having to be milled. The article talks about a process to make LM sheets, which is likely not the target shape, but perhaps could be used as raw material for such molds. [/quote] That's not the 'whole point' of LM at all. Liquid metal's advantages stem from the fact that it's amorphous rather than crystalline. That gives it a number of very useful advantages: - Less brittle - Less prone to work hardening - More resilient - Less corrosion - Stronger (due to lack of stress concentration sites). All of those advantages apply to stamped parts every bit as much as machined parts. In fact, some of them ONLY apply to stamped parts (such as the work hardening advantage).