A decade after Apple and Samsung partnered to create a new class of ARM chips, the two have followed separate paths: one leading to a family of world-class mobile silicon designs, the other limping along with work that it has now canceled. Here's why Samsung's preoccupation with unit sales and market share failed to compete with Apple's focus on premium products.

Apple's custom "Thunder" and "Lightning" cores used in its A13 Bionic continue to embarrass Qualcomm's custom Kyro cores used in its Snapdragon 855 Plus, currently the leading premium-performance SoC available to Android licensees.

The A13 Bionic is a significant advancement of Apple's decade-long efforts in designing custom CPU processor cores that are both faster and more efficient than those developed by ARM itself while remaining ABI compatible with the ARM instruction set. Other companies building "custom" ARM chips, including LG's now-abandoned NUCLUN and Huawei's HiSilicon Kirin chips, actually just license ARM's off-the-shelf core designs.

To effectively compete with Apple and Qualcomm, and stand out from licensees merely using off-the-shelf ARM core designs, Samsung's System LSI chip foundry attempted to develop its own advanced ARM CPU cores, initiated with the 2010 founding of its Samsung Austin R&D Center (SARC) in Texas. This resulted in Samsung's M1, M2, M3, and M4 core designs used in a variety of its Exynos-branded SoCs.

The company's newest Exynos 9820, used in most international versions of its flagship Galaxy S10, pairs two of its M4 cores along with six lower power ARM core designs. Over the past two generations, Samsung's own core designs have, according to AnandTech, delivered "underwhelming performance and power efficiency compared to its Qualcomm counter-part," including the Snapdragon 855 that Samsung uses in U.S. versions of the Galaxy S10.

The fate of Samsung's SARC-developed M-series ARM cores appeared to be sealed with reports earlier this month that Samsung was laying off hundreds of staff from its chip design team, following the footsteps of Texas Instruments' OMAP, Nvidia Tegra, and Intel Atom in backing out of the expensive, high-risk mobile SoC design space. It is widely expected that Samsung will join Huawei in simply repackaging ARM designs for future Exynos SoCs.

This development highlights the vast gap between what Apple has achieved with its A-series chips since 2010 compared to Samsung's parallel Exynos efforts over the same period. This is particularly interesting because in 2010 Apple and Samsung were originally collaborators on the same ancestral chip of both product lines.

Partners for a new Apple core

In 2010, Samsung and Apple were two of the world's closest tech partners. They had been collaborating to deliver a new ARM super-chip capable of rivaling Intel's Atom, which scaled-down Chipzilla's then-ubiquitous x86 chip architecture from the PC to deliver an efficient mobile processor capable of powering a new generation of tablets.

ARM processors had been, by design, minimally powerful. ARM had originated in a 1990 partnership between Apple, Acorn, and chip fab VLSI to adapt Acorn's desktop RISC processor into a mobile design Apple could use in its Newton Message Pad tablet. Across the 1990s, Newton failed to gain much traction, but its ARM architecture processor caught on as a mobile-efficient design popularized in phones by Nokia and others.

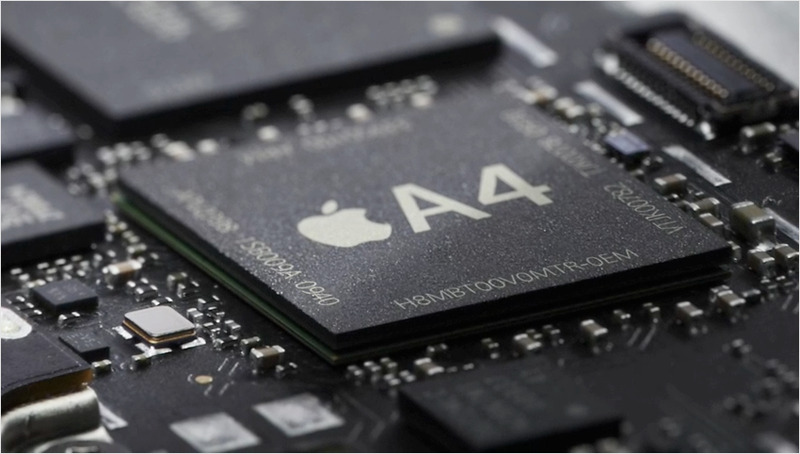

Starting in 2001, Apple began using Samsung-manufactured ARM chips in its iPods, and since 2007, iPhone. The goal to make a significantly more powerful ARM chip was launched by Apple in 2008 when it bought up P.A. Semi. While it was widely reported that Apple was interested in the company's PWRficient architecture, in reality, Apple just wanted the firm's chip designers to build the future of mobile chips, something Steve Jobs stated at the time. Apple also partnered with Intrinsity, another chip designer specializing in power-efficient design, and ended up acquiring it as well.

Samsung's world-leading System LSI chip fab worked with Apple's rapidly assembled design team with talent from PA Semi and Intrinsity to deliver ambitious silicon design goals, resulting in the original new Hummingbird core design, capable of running much faster than ARM's reference designs at 1 Gigahertz. Apple shipped its new chip as A4, and used it to launch its new iPad, the hotly anticipated iPhone 4, and the new Apple TV, followed by a series of subsequent Ax chip designs that have powered all of its iOS devices since.

Frenemies: from collaborators to litigants

The tech duo had spent much of the previous decade in close partnership, with Samsung building the processors, RAM, disks and other components Apple needed to ship vast volumes of iPods, iPhones and now, iPad. But Samsung began to increasingly decide that it could do what Apple was doing on its own, simply by copying Apple's existing designs and producing more profitable, finished consumer products on its own.

Samsung's System LSI founded SARC and went on to create its independent core design and its own line of chips under its Exynos brand. That effectively forced Apple to scale up its chip design work, attempt to second-source more of its components and work to find an alternative chip fab.

Increasing conflicts between the two tangled them in years of litigation that ultimately resulted in little more than a very minor windfall for Apple and an embarrassing public view into Samsung's ugly copy-cat culture that respected its own customers about as little as its criminal executives respected bribery laws.

As Samsung continued to increasingly copy Apple's work to a shameless extent, it quickly gained positive media attention for selling knockoffs of Apple's work at cut-rate prices. But it took years for Apple to cultivate alternative suppliers to Samsung, and it was particularly daunting for Apple to find a silicon chip fab partner that could rival Samsung's System LSI chip fab.

Samsung takes its act solo

By 2014, Samsung had delivered years of nearly identical copies of Apple's iPhones and iPads, and its cut-rate counterfeiting had won the cheering approval and endorsement of CNET, the Verge and Android fan-sites that portrayed Samsung's advanced components as the truly innovative technology in mobile devices, while portraying Apple's product design, OS engineering, App Store development, and other work as all just obvious steps that everyone else should be able to copy verbatim to bring communal technology to the proletariat. Apple was disparaged as a rent-seeking imperialist power merely taking advantage of component laborers and fooling customers with propaganda.

What seemed to escape the notice of pundits was the fact that while Samsung appeared to be doing an okay job of copying Apple's work, as it peeled away to create increasingly original designs, develop its own technical direction, and pursue software and services, the Korean giant began falling down.

Samsung repeatedly shipped fake or flawed biometric security, loaded up its hardware with a mess of duplicated apps that didn't work well at all, splashed out technology demos of frivolous features that were often purely ridiculous, and repeatedly failed to create a loyal base of users for its attempted app stores, music services, or its own proprietary development strategies.

And despite the vertical integration of its mobile device, display, and silicon component divisions that should have made it easier for Samsung to deliver competitive tablets and create desirable new categories of devices including wearables, its greatest success had merely been creating a niche of users who liked the idea of a smartphone with a nearly tablet-sized display, and were willing to pay a premium for this.

Despite vast shipments of roughly 300 million mobile devices annually, Samsung was struggling to develop its custom mobile processors. In part, that was because another Samsung partner, Qualcomm, was leveraging its modem IP to prevent Samsung from cost-effectively even using its own Exynos chips. For some reason, the communist rhetoric that tech journalists used to frame Apple as a villainous corporation pushing "proprietary" technology wasn't also applied to Qualcomm.

Apple's revenge on a cheater

Unlike Samsung, Apple wasn't initially free to run off on its own. There simply were not any alternatives to some of Samsung's critical components— especially at the scale Apple needed.

In particular, it was impossible for Apple to quickly yank its chip designs from Samsung's System LSI and take them to another chip fab, in part because a chip design and a particular fab process are extremely interwoven, and in part because there are very few fabs on earth capable of performing state of the art work at scale. Perhaps four in total and each of those fabs' production was booked up because fabs can't afford to sit idle.

It wasn't until 2014, after several years of exploratory work, that Apple could begin mass producing its first chip with TSMC, the A8. That new processor was used to deliver Apple's first "phablet" sized phones, the iPhone 6 and iPhone 6 Plus. These new models absolutely eviscerated the profits of Samsung's Mobile IM group. The fact that their processors were built by Samsung's chip fab arch-rival was a particularly vicious twist of the same blade.

Apple debuted the iPhone 6 alongside a preview of Apple Watch. A few months later, Apple Watch went on sale and rapidly began devastating Samsung's flashy experiment with Galaxy Gear — the wearable product line it had been trying to sell over the past two years. Galaxy Gear had been the only significant product category that Samsung appeared capable of leading in, simply because Apple hadn't entered the space. Now that it had, Samsung's watches began to look as commercially pathetic as its tablets, notebooks, and music players.

Samsung's inability to maintain its premium sales and its attempts to drive unit sales volume instead with downmarket offerings hasn't resulted in the kind of earnings that Apple achieves by selling buyers premium products that are supported longer and deliver practical advancements.

As a result, Apple is now delivering custom silicon not just for tablets and phones, but also for wearables and a series of specialized applications ranging from W2 and H1 wireless chips that drive AirPods and Beats headphones, to its T2 security chips that handle tasks like storage encryption, media encoding, and Touch ID for Macs.

Daniel Eran Dilger

Daniel Eran Dilger

-m.jpg)

Marko Zivkovic

Marko Zivkovic

Mike Wuerthele

Mike Wuerthele

Christine McKee

Christine McKee

Amber Neely

Amber Neely

Sponsored Content

Sponsored Content

Wesley Hilliard

Wesley Hilliard

William Gallagher

William Gallagher

34 Comments

Imagine in the not too distant future ... Apple exclusive microLED displays, Apple’s own 5G chips, and Apple memory chips combined with TSMC 5nm fabrication starting with the A14 - now that would demolish the competition. No more costly reliance on Samsung and Qualcomm.

Still not sure why others can’t achieve what Apple can in chip design. And, while every editorial praises Apple’s approach (concentrating on premium devices only), there must be companies making cheap devices. There’s nothing wrong with being a cheap device producer. You obviously can’t make more money from cheap devices as they priced less than Apple’s margin on iPhones.