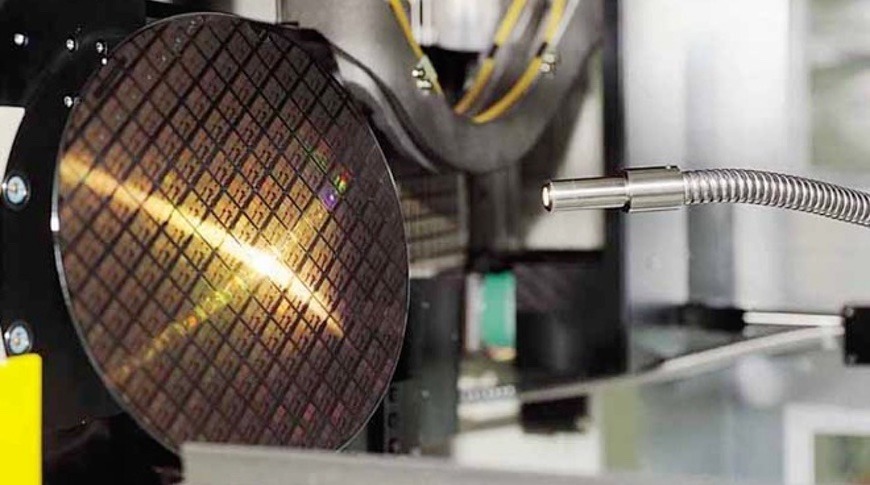

Apple manufacturing partner TSMC is on track to start producing chips using a 3nm chip fabrication process in late 2022, and is already working on improved 5nm processes.

Like other chip makers, TSMC has been working to develop processes at smaller nanometer levels, with some of its research going into creating 3-nanometer production processes. At that level, it is claimed TSMC has started to construct production lines and related facilities for creating 3-nanometer chips.

The 3-nanometer project is still on schedule, according to DigiTimes, with risk production anticipated to take place in 2021 followed by volume production in the second half of 2022. If accurate, and based on typical iPhone production schedules, this could lead to the Apple-designed A15 at the absolute earliest or more realistically, the A16 chip in 2022 using the process.

For the more immediately accessible 5-nanometer chips, TSMC is said to be in volume production with the technology, but it is already working on improved versions. The company is said to be creating more processor variants, including a further-enhanced 5nm node that expands on the existing 5nm Plus node.

It is thought Apple is using TSMC's 5nm processes to create the next generation of A-series chips destined for the "iPhone 12" tentatively titled the "A14," with production scheduled for mid-2020. In April, it was reported Apple increased its chip order for the fourth quarter of 2020, potentially due to an anticipated higher demand for the annual iPhone refresh.

TSMC is also intending to move some of its chip production to the United States, in a factory in Arizona thought to cost $12 billion. It Is far from operational, with construction commencing in 2021 and chip production expected to start in 2024, but it offers the prospect of some A-series chips being made on US soil.

Malcolm Owen

Malcolm Owen

Wesley Hilliard

Wesley Hilliard

Stephen Silver

Stephen Silver

William Gallagher

William Gallagher

Charles Martin

Charles Martin

Marko Zivkovic

Marko Zivkovic

Andrew Orr

Andrew Orr

Amber Neely

Amber Neely

16 Comments

TSMC is a huge reason why Apple is going all in on their own ARM chips in all their products. Always encouraging to see progress towards the next node.

This fab is almost like the Foxconn thing. A fab this small and with technology that will be that old when the factory starts production is meaningless in the global scope.

Holy cow! 5nm to 3nm? A 40% size reduction in 2 years? That’s is just crazy.

“DigiTimes”... say no more. SMDH.

How is it even remotely possible? How do they deal with thermal noise and leakage?