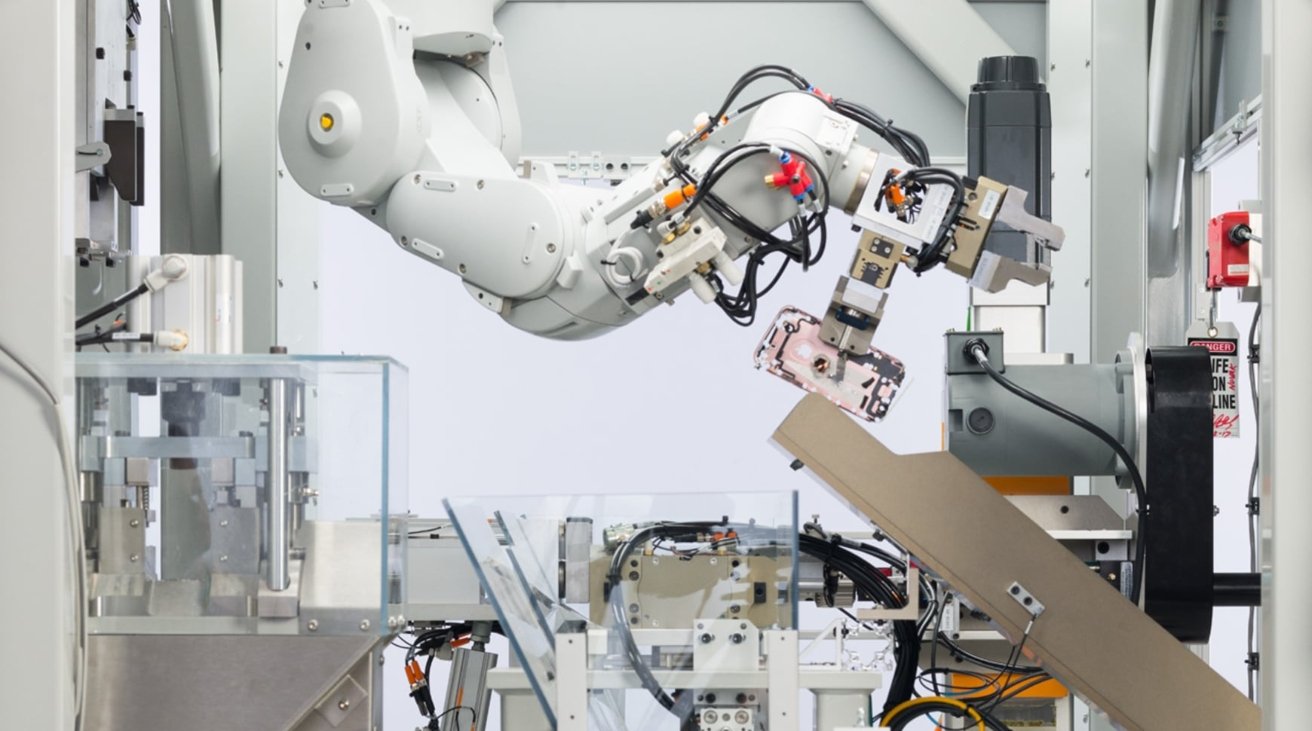

Apple's disassembly robot and entire iPhone recycling process is an extremely complex effort, and has integrated safety features to minimize the risk and impact of battery explosions.

As part of its efforts to reduce digital waste and to reclaim materials, in part to reduce the amount of mining that takes place, Apple uses robots to quickly and neatly disassemble iPhones submitted for recycling.

Its first effort, "Liam," was introduced in 2016 to critical acclaim, while 2018 brought with it the upgraded "Daisy." However, outside of occasional appearances to bolster Apple's environmental credentials, the company hasn't really gone into detail about how each robot works.

In a pair of patents granted by the US Patent and Trademark Office on Tuesday and both titled "Modular system for automated portable electronic device disassembly," Apple explains some of the methods it employs with its robots. It also covers some of the logistics that can come into play when dealing the mass disassembly of hardware.

Apple refers to a "thermal event" a few times in the patent claims, which is referring to a battery rupture. A ruptured battery can be a hazard to both humans and machinery, as evidenced by Samsung's Note battery issues.

"It will be appreciated that the battery includes chemicals used to store energy," explains one patent. "Automated disassembly can sometimes pierce or otherwise damage the battery, which increases the chances of a runaway thermal event due to chemical reactions."

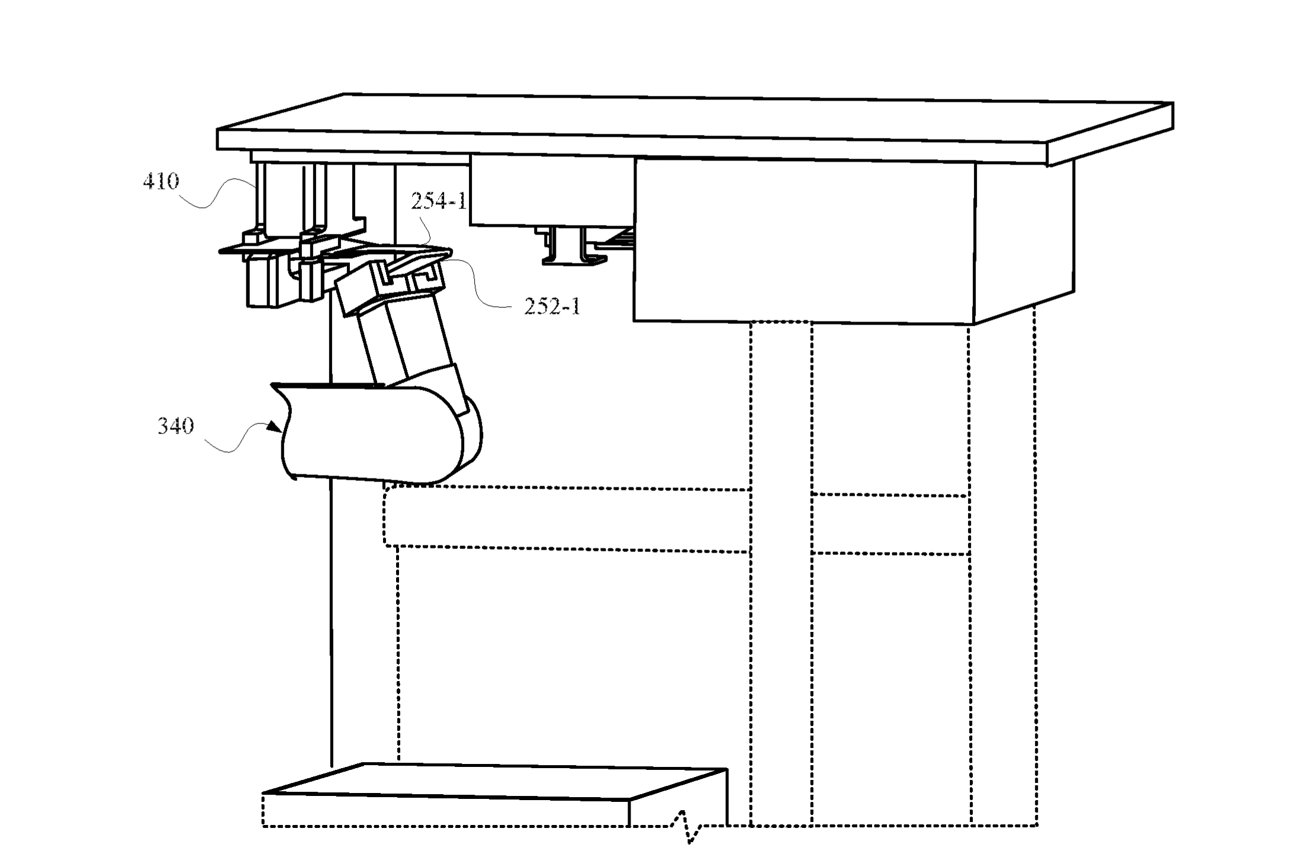

The first patent, number 11,045,913, explains a method for disassembling a portable electronic device, which is shown in images to be an iPhone. The patent covers how the system is inherently modular, with each module handling a different phase of the disassembly process.

For each device that goes into the system, data is generated about the device, typically by a camera, which makes measurements of the housing. Based on these measurements, the first module removes the display assembly, while a second pulls the battery, followed by other modules performing similar tasks.

The modules are able to communicate with each other, store instructions for disassembly based on the measurements of the housing, sense for components, detect the rate a device housing is heating up or cooling, and bend angles of the housing.

Swinging arms are used to pull batteries from glue, while cooling units reduce the temperatures of components that may have been warmed during the process.

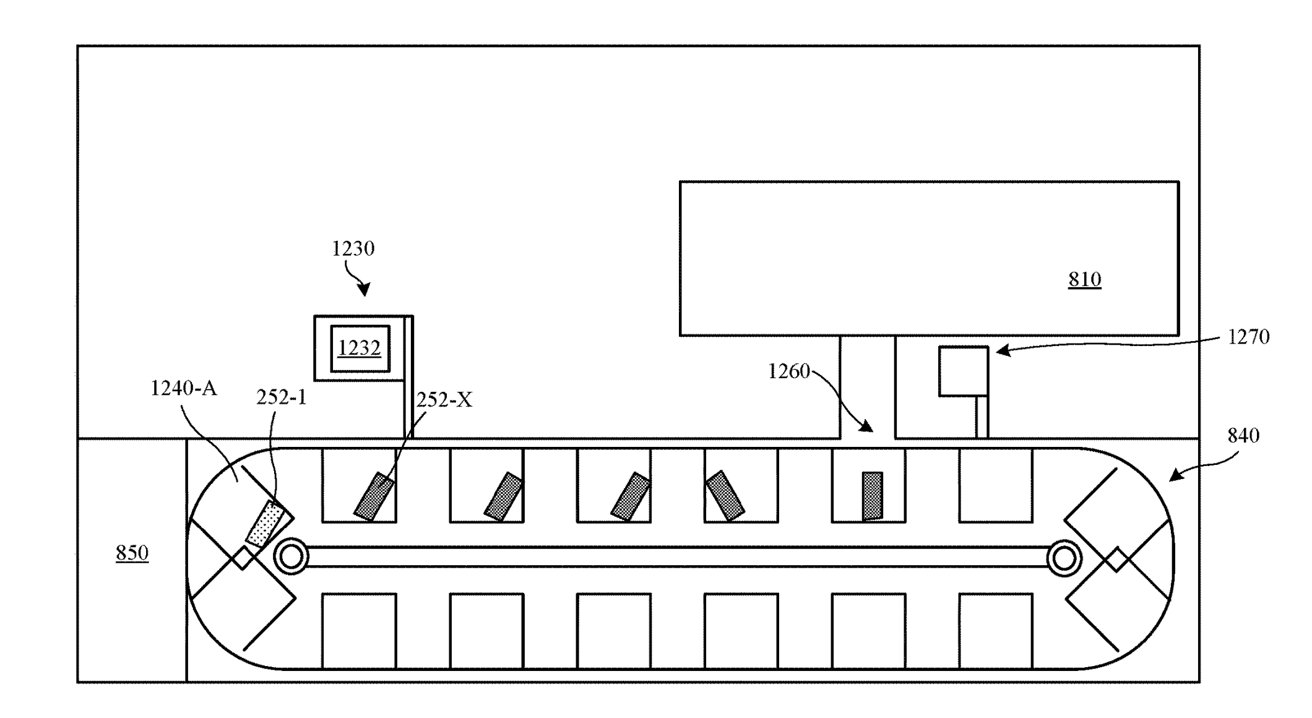

The second patent, 11,051,441, follows the same subject area, but largely deals with the logistics side rather than disassembly itself, and even more so about detecting and managing temperatures.

Using a conveyor to transport the devices between modules, the system is able to deposit extracted parts and components to a receiving station. The devices, and pulled parts, are stored in a container that moves along the belt, one which is non-conductive and potentially lined with a flame-retardant material.

At various times, the system will monitor the temperature of the container and its contents using a thermal imaging camera. This is to ensure the device is not too hot to pull from the container that it would be a hazard to the disassembly process itself.

If the device exceeds a permitted temperature threshold range associated with a stage of disassembly, the container will be stopped and prevented from moving on until the temperature drops to a suitable level.

Another version of the conveyor system can include a "movable train," with containers that have sensors to detect the presence of components. If a component is detected, the train can be activated to move from one station to another.

A thermal sensor could be used as well, to monitor the temperature of components, which again can warn if the part is too hot.

Thermal events appear a few times towards the end, including defining the container as a "thermal event containment container." There is also the suggestion the system could be "maintained at a negative pressure such as to prevent any gas associated with the electronic component reaching a thermal event from escaping the system."

A controller can be configured to prevent a part from being removed at the removal station if a thermal event is reached. This could be read as Apple not wanting to deposit a rupturing battery in a pile with other batteries, so as to avoid a chain reaction of battery failures.

The patents were filed on April 12, 2019.

The first patent lists its inventors as Patrick S. Wieler, Charissa Rujanavech, Mark Lewis, Thomas Loeper, Dan Powell, Jason Schwarz, Jon Sever, and Darragh Stauntion. The second was invented by Patrick S. Wieler, Charissa Rujanavech, Sean P. Shannon, James Fikert, Roy Mahalas, Dan Powell, and Jason Schwarz.

Apple files numerous patent applications on a weekly basis, but while the existence of a patent indicates areas of interest for Apple's research and development teams, it doesn't guarantee the ideas will appear in a future product or service.

It is unclear if Apple employs any of the measures outlined in the patents, but it seems plausible that it has taken steps to make its workspace as safe as possible to work within.

While Apple has embraced using a robot to take apart an iPhone, the same cannot be said for device assembly. The company is working to automate its production lines, but its assembly partners still rely on armies of workers on production lines to put the parts together.

Apple has also explored the possibility of using robots in products for consumers. In the case of one September 2019 patent, Apple suggested a small robot could scurry across a garage floor and plug a charger underneath an Apple Car.

Keep up with everything Apple in the weekly AppleInsider Podcast — and get a fast news update from AppleInsider Daily. Just say, "Hey, Siri," to your HomePod mini and ask for these podcasts, and our latest HomeKit Insider episode too.

If you want an ad-free main AppleInsider Podcast experience, you can support the AppleInsider podcast by subscribing for $5 per month through Apple's Podcasts app, or via Patreon if you prefer any other podcast player.

Malcolm Owen

Malcolm Owen

-m.jpg)

Marko Zivkovic

Marko Zivkovic

Mike Wuerthele

Mike Wuerthele

Christine McKee

Christine McKee

Amber Neely

Amber Neely

Wesley Hilliard

Wesley Hilliard

William Gallagher

William Gallagher

4 Comments

I've love to see these robots in action.

I wonder if this expertise in disassembling something as intricate as an iPhone could be used elsewhere to help with waste management/recycling.