Apple's aluminum strategy aids shift to greener products

In 2007, Apple CEO Steve Jobs penned an open letter highlighting changes to the company's environmental policy in hopes of achieving "a greener Apple." In the letter, Jobs specifically noted the Cupertino, Calif., Mac maker's adoption of aircraft-grade aluminum in order to improve recycling uptake.

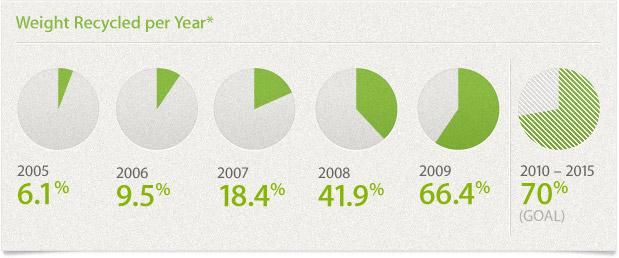

At the time, Jobs forecast that Apple would increase recycling effectiveness, which is measured by calculating the total weight recycled in a given year divided by the total weight sold seven years prior, from 9.5 percent in 2006 to 28 percent in 2010. The company has been remarkably successful in its efforts, achieving a 66.4 percent recycle rate in 2009 and setting a goal of 70 percent for 2010-2015.

Recycled aluminum requires just 5 percent of the energy needed to produce primary aluminum, while emitting 95 percent less green house gases. According to Klaus Kleinfeld, CEO of aluminum giant Alcoa, the metal is "infinitely recyclable," with 75 percent of all aluminum produced since 1888 still in active use today.

Alcoa sees rapid growth of aluminum in the electronics market, as evidenced by its recent acquisition of a minority stake in Electronics Recycling International, the largest recycler of electronics waste in the U.S. "Consumer electronics represents a fast-growing market for aluminum, with the aluminum content in laptops alone expected to increase 30 per cent by 2013 from a 2010 baseline," said Chief Sustainability Officer Kevin Anton.

Apple popularized aluminum laptops in 2003 with the introduction of the aluminum PowerBook G4. In 2008, the company outdid itself by implementing a custom-developed aluminum unibody enclosure for the release of the MacBook Air and later the MacBook and MacBook Pro. The unibody manufacturing process utilizes "computer numerical control" machines to carve a chassis out of one block of aluminum.

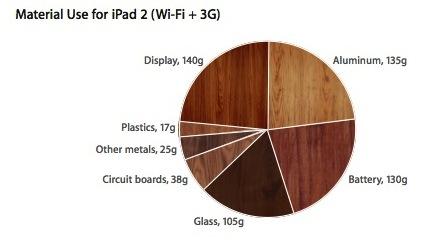

Aluminum has made its way to Apple's post-PC products as well, within an appearance in various versions of the iPod, iPhone and iPad. Apple indicated in its recent Environmental Report for the iPad 2 that the device's aluminum casing is "highly desired by recyclers." Although, interestingly enough, the second-generation tablet requires slightly more aluminum (135 g compared to 125 g) than its predecessor, despite being 15 percent lighter.

Some reports have speculated that the concurrent release of the white model of the iPad 2 was made possible because its aluminum back does not suffer from the same light leakage issues as the iPhone 4's glass panels. The white iPhone 4 was announced last year, but was delayed by Apple until this spring.

Given Apple's frequent use of aluminum in its products, speculation has emerged that the next-generation iPhone will feature an aluminum back. The original iPhone used an aluminum back, but was phased out in favor of a plastic back on the iPhone 3G and iPhone 3GS.

The iPhone 4 currently sports front and rear glass panels and a stainless steel outer frame that doubles as an antenna. Apple's decision to use the frame as an antenna drew criticism last summer after some users reported dropped calls and reduced signal bars when gripping the phone.

Josh Ong

Josh Ong

Amber Neely

Amber Neely

Thomas Sibilly

Thomas Sibilly

AppleInsider Staff

AppleInsider Staff

William Gallagher

William Gallagher

Malcolm Owen

Malcolm Owen

Christine McKee

Christine McKee

54 Comments

Being greener is just a bonus to the fact that it is the best looking, best built laptop ever. The engineering and manufacturing is top notch compared to all the others which seen like they are designed and slapped together just to get them out the door in time.

It's highly recyclable, strong, beautiful and lovely to the touch. Why on earth is Apple the only company using it as a primary material in their computer chassis? I wouldn't buy a plastic computer now. I love waking up in the morning and feeling the cold metal of my MacBook Pro when I start work. It's a huge step forward in laptop quality.

The factoid about 75% of all aluminium produced since 1888 still being in use is astonishing.

It's highly recyclable, strong, beautiful and lovely to the touch. Why on earth is Apple the only company using it as a primary material in their computer chassis? I wouldn't buy a plastic computer now. I love waking up in the morning and feeling the cold metal of my MacBook Pro when I start work. It's a huge step forward in laptop quality.

The factoid about 75% of all aluminium produced since 1888 still being in use is astonishing.

Apple has had to invent machining techniques to pull off the unibody design. Other companies are incapable of doing similar stuff.

I was surprised that the latest Apple TV has a plastic case. Maybe that's just an interim design, before Apple either goes to an aluminum enclosure or embeds the circuit board into OEM HDTV sets.

So maybe Apple's purchase of Liquid Metal was for developing techniques for "injection molding" aluminum the way Liquid Metal does it with their platinum-based alloy. As slick and scratch-resistant as the Liquid Metal alloy is, the material cost may be too high for use in enclosures as big as MacBook Pros, Airs, iMacs, Mac Pros and the like. And if it's hard to recycle for whatever reason, that too could be a deal killer. (Maybe Apple could offer a discount to owners who trade in their old Apple products for recycling...)

Why "injection molding" (quoted because the Liquid Metal process is far more advanced than just injection molding)? Because as difficult as the process is to set up, it must take far less time than grinding out all that aluminum from a solid billet. Instead of forming the billet and machining 80% of it out, you could just form the enclosure. Boom.

While I'm certainly PRO-recycling and appreciate products that are designed to be recyclable, I don't get why people get SO excited about the _recyclability_ of what should be highly durable products. I loved my aluminum MBP and my brand spanking new unibody MBP because they are rock solid _durable_ laptops...

In fact I'm willing to bet that the vast majority of MacBook buyers throw far more aluminium in the non-recyclable trash bin every year than there is in one MacBook...

I'm just saying that for ME, even being very pro-recycling, I don't think much about my laptops end of life and care more durability and reduction of toxins.