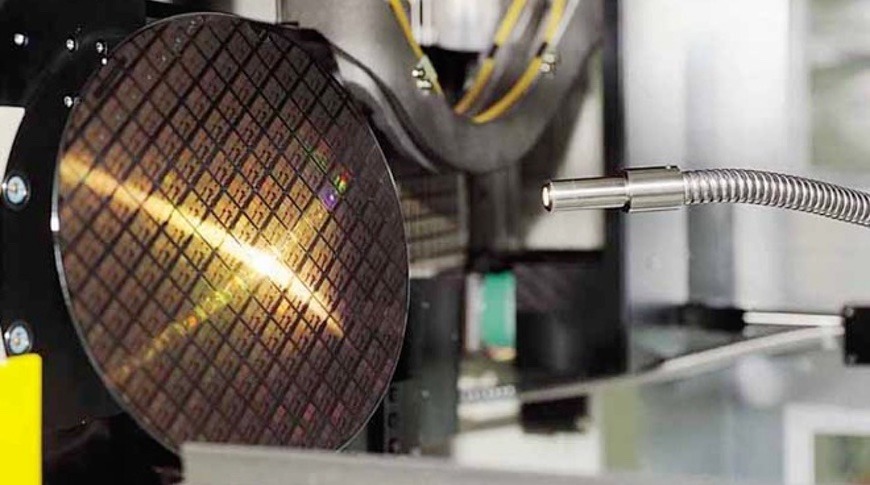

TSMC's 5-nanometer process may start with Apple 'A14' in early 2020

Apple could shift the 2020 A-series processor to a 5-nanometer production process, comments from TSMC CFO Lora Ho suggests, with a shift to mass production of the processor architecture node tipped to commence in the first half of 2020, spurred on by 5G smartphone demands.

Apple's iPhone and other smartphones are expected to be the main driver of growth for TSMC's third quarter alongside Internet of Things devices, CFO Lora Ho advised, in explaining the anticipated increase in demand in the second half of 2019, as revealed by the company on Thursday. The fourth quarter will be even stronger, furthered by higher smartphone chip demand.

The growing demand for 5G smartphones and base station equipment will be a main driver for component demand for the rest of the year, Ho told DigiTimes, with the company using its advanced and mature process nodes for chip production in those fields for the moment.

The demand is sufficiently strong that the company's capital expenditure will outpace a previous estimation of $10 billion to $11 billion, with increased spending planned for both current-generation 7-nanometer process and newer 5-nanometer nodes.

CEO C.C. Wei told investors on Thursday TSMC has become "a little bit more aggressive" on its 5-nanometer production ramp up, with the producer on track to go to volume production of 5-nanometer chips by the first half of 2020. Wei suggested the growth of 5G demand will spur on a need for greater 5-nanometer and 7-nanometer production.

The development of a 5-nanometer process node would offer benefits to TSMC clients that opt for it, including Apple. This can include shrinking the physical space of the die, reducing the cost-per-chip of wafers and the ultimate cost of the processor, improved performance, and lower power consumption.

For Apple, the current-generation A12 Bionic is made using a 7-nanometer process, while the "A13" expected in this fall's iPhone refresh is tipped to stay at that tier. TSMC has already provided its design infrastructure for creating 5-nanometer process chips to clients, and since Apple is a major customer of the chip foundry, it is likely to be among the first to take advantage of the technology when it is ready for production, possibly in the "A14" chip.

Malcolm Owen

Malcolm Owen

Amber Neely

Amber Neely

Thomas Sibilly

Thomas Sibilly

AppleInsider Staff

AppleInsider Staff

William Gallagher

William Gallagher

Christine McKee

Christine McKee

18 Comments

Every time I see these articles I wonder when will the shrinking (advancements) stop...

I realize 5-nanometer isn’t really 5-nanometer and is more marketing, but still the shrinking continues.

We’re getting real close to the physical limits, then things get interesting.

My “interesting” expectation is 2025, or 2 generations away.

The Intel 80286 was released in 1982. It has 134k transistors at a 1.5µm feature size. That's 1500nm. If the processes could be directly compared, 1500nm to 5nm means transistors in the new process are 1/300th the linear size, which means 1/90,000 the area. You could just about fit an entire 80286 core into every other transistor of the original 80286.

They're not directly comparable, of course. Only certain features can be 5nm, while others must be larger. Still, the 80186 (also from 1982) was 55k transistors with a 3µm feature size. That yields 600x linear improvement and 360,000x area improvement. Even considering some features need to be larger than 5nm, you could definitely fit an entire 80186 core into each transistor of an original 80186.

I remember back when they used to say anything smaller than 9 nanometers would be difficult, if not impossible! The bar for what is impossible keeps being raised.

The diameter of a silicon atom is about 110 picometers, or 0.11 nanometers. That means the smallest feature on these chips would be about 50 atoms wide. We truly are approaching atomic computing. Maybe they'll have to switch to a smaller atom like hydrogen!